When exploring the domain of 3D printing imperfections, you'll find a fascinating interplay between various factors that influence the final outcome of your prints. From the nuances of acceleration and jerk settings to the intricate dance of ghosting, jerking, and ringing, each imperfection tells a story of its own. As you investigate further into this world, you'll uncover the secrets behind achieving impeccable print quality and consistency. But beware, the specter of imperfections may just have a few surprises in store for you, urging you to seek out solutions that lead to flawless prints.

Understanding Ghosting, Jerking, and Ringing

If you're experiencing visual imperfections like ghosting, jerking, or ringing in your 3D prints, you're likely dealing with rapid changes in your printer's direction causing these issues.

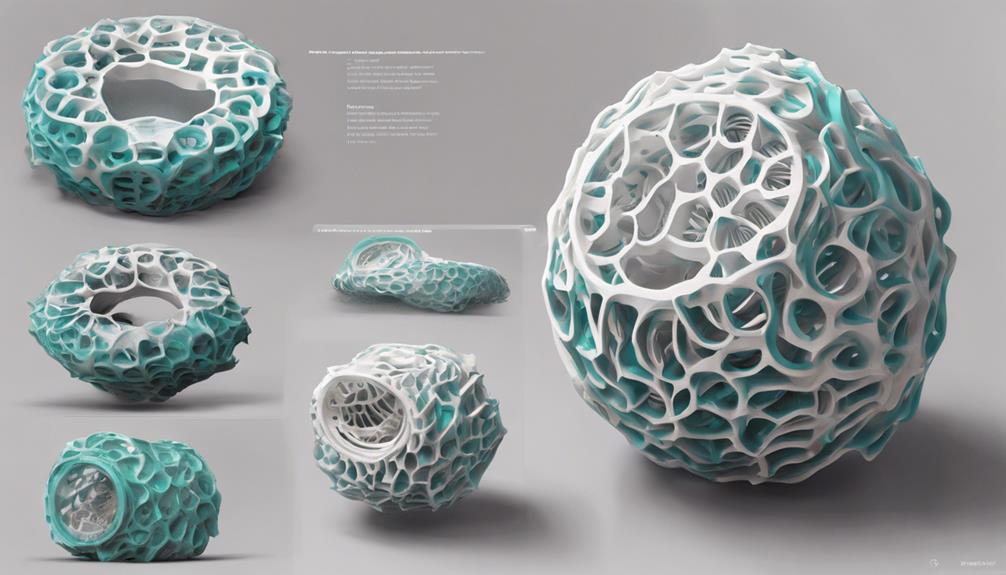

Ghosting, jerking, and ringing manifest as patterns or echoes on your prints, affecting their appearance. Ghosting, specifically, appears as repeated features across the print's surface, often mistaken for visible infill by beginners. Vibrations from the printer's rapid movements cause ghosting, emphasizing the importance of stable printing conditions.

To address these imperfections, understanding the impact of acceleration and jerk settings is essential. Tailoring these settings based on your desired output can greatly improve print quality and reduce ghosting. Adjusting acceleration and jerk settings helps in achieving smoother prints with better detailing.

Detecting and Testing for Ghosting

When detecting and testing for ghosting in 3D prints, closely observe the surface for repeated features and patterns. Look for any echoes or duplicated details that shouldn't be present. By examining the print closely, you can detect subtle signs of ghosting.

Pay attention to how the printer parts move during printing as this can also give you clues about potential ghosting issues. Keep in mind that factors like the weight of the X gantry and print settings such as speed, acceleration, and jerk play a significant role in the likelihood of ghosting.

Testing for ghosting involves printing objects and inspecting sharp edges and repeated details for any signs of ghosting.

Impact of Acceleration and Jerk Settings

To understand the impact of acceleration and jerk settings on 3D prints, closely assess their influence on print quality and surface finish.

- Higher acceleration and jerk settings can lead to faster printing times but may result in decreased print quality.

- Tailoring these settings based on your desired output is essential for achieving a balance between speed and quality.

- Standard acceleration and jerk settings are recommended to minimize printing resonance and improve detailing.

- Adjusting these settings appropriately can help reduce imperfections like ghosting on your 3D prints.

Recommended Acceleration and Jerking Settings

For best 3D print quality, adhere to suggested acceleration and jerking settings to minimize imperfections like ghosting. The standard acceleration setting is 60mm/s, with a jerk setting of around 10mm/s. It's essential to adjust these settings based on your specific printer model to optimize print quality.

Higher quality printers may require different settings for best results. Proper acceleration and jerk settings lead to improved overall print quality, consistency, and precision. By tailoring these settings, you can reduce issues like rough printing surfaces and noisy operation.

Remember that adjusting acceleration and jerk settings plays an important role in solving problems like ghosting, ensuring your prints turn out smooth and flawless.

Solutions for Ghosting Issues

Optimize your 3D printing process by implementing effective solutions to address ghosting issues and enhance the quality of your prints.

- Adjust Acceleration and Jerk Settings: Set them to recommended values to minimize ghosting.

- Control Printing Speed: Prevent violent vibrations that cause ghosting by managing the speed.

- Enhance Printer Rigidity: Tighten loose belts and consider upgrades like vibration dampeners.

- Customize Settings: Tailor settings based on your specific printer model for best results.

Enhancing Printer Rigidity and Upgrades

Enhance your 3D printing results by focusing on increasing the rigidity of your printer and exploring potential upgrades for improved performance. Vital is imperative to reduce vibrations that lead to imperfections like ghosting. Tighten belts and consider upgrades such as installing vibration dampeners to stabilize your printer.

Upgrading components like stepper motors, hotends, or adding a sturdy frame can enhance overall print quality by minimizing wobbling during printing. Additionally, reinforcing weak points in your printer's structure with braces or supports can further improve rigidity.

Optimizing Settings for Quality Prints

Improving print quality in 3D printing involves precisely adjusting acceleration and jerk settings to minimize imperfections like ghosting. To optimize your settings for quality prints, follow these steps:

- Set acceleration to 60mm/s and jerk to around 10mm/s as standard values.

- Customize settings based on your specific printer model for best results.

- High-quality printers may require different settings to achieve the finest outcomes.

- Properly adjusting acceleration and jerk settings will lead to improved print quality, consistency, and precision.

Frequently Asked Questions

How Can I Differentiate Between Ghosting and Visible Infill in 3D Prints?

To differentiate between ghosting and visible infill in 3D prints, observe repeated features for ghosting, while visible infill appears as solid sections. Ghosting stems from rapid movements causing vibrations, which are distinct from infill patterns.

What Are the Potential Consequences of Ignoring Ghosting in 3D Printing?

Ignoring ghosting in 3D printing can lead to visible imperfections like repeated patterns and echoes on prints. Failure to address this issue can compromise print quality, affecting the overall appearance and precision of your creations.

Can Ghosting Be Completely Eliminated, or Is It an Inherent Limitation?

You can minimize ghosting in 3D prints by adjusting acceleration and jerk settings. While complete elimination may be challenging due to printer limitations, optimizing settings and enhancing printer rigidity can greatly reduce ghosting for improved print quality.

Are There Any Software Tools Available to Help Diagnose Ghosting Issues?

If you want to diagnose ghosting issues, check out software tools. They help by analyzing print patterns for signs of ghosting. Observing these details can guide adjustments to your printer settings, enhancing print quality.

How Do Different Filament Types Impact the Visibility of Ghosting on Prints?

When printing, filament types subtly affect ghosting visibility on prints. Experiment with different materials to find what works best for you. Tailoring filament choices to reduce ghosting can enhance your final 3D prints.

Conclusion

You've learned how to tackle ghosting, jerking, and ringing in your 3D prints. By adjusting acceleration and jerk settings, you can minimize these imperfections and achieve better quality prints.

Did you know that according to a study, optimizing these settings can reduce ghosting by up to 80%?

Keep fine-tuning your printer settings and don't let imperfections haunt your prints!