As you navigate the intricate world of 3D printing, mastering the terminology is essential for honing your skills and creating high-quality prints. Imagine confidently discussing topics like filament types, material properties, 3D printer parts, and troubleshooting terms with fellow enthusiasts and professionals alike. This glossary equips you with the knowledge needed to elevate your understanding and expertise in the domain of 3D printing. Explore the intricacies of this dynamic field and access a world of possibilities through a deeper comprehension of its terminology and applications.

Filament Types

When selecting filament types for your 3D printing projects, consider the properties and characteristics of each option to ensure the best results.

ASA filament offers superior weather resistance and UV resistance, making it ideal for outdoor applications due to its rigid and impact-resistant nature.

ABS filament is a popular choice with high-temperature resistance but prone to warping without a heated print bed or chamber.

PETG filament, semi-rigid with a smooth surface finish, is more flexible and durable than PLA, although it requires proper storage in a dry place.

PLA, the most commonly used filament, is easy to print with low temperatures but deforms in sunlight, making it unsuitable for outdoor use.

Nylon filament, strong and flexible, requires high printing temperatures and careful moisture prevention for top-notch results.

Material Properties

Understanding material properties is essential for achieving successful 3D prints with the desired characteristics and performance. Here are some key aspects to keep in mind:

- Glass Transformation Temperature (Tg): Determines a material's flexibility.

- Tensile Strength: Indicates material stress tolerance.

- Conductivity: Measures heat or electricity conduction ability.

- Elasticity: Shows the material's deformation and recovery capability.

Each of these properties plays an important role in determining how a material will behave during the 3D printing process and in the final printed object. Paying attention to these characteristics will help you select the right filament for your specific printing needs.

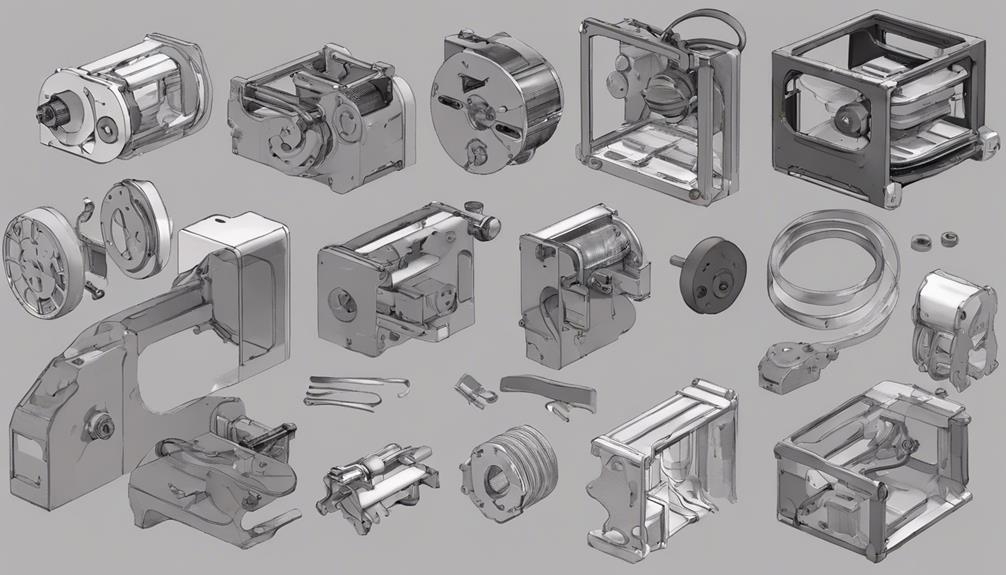

3D Printer Parts

To understand the mechanics of a 3D printer, familiarize yourself with its essential components. The controller board acts as the brain, handling electronic functions and translating commands for motors.

The extruder manages filament movement, consisting of a cold end and hot end. The nozzle is where the filament travels through, with various diameters and materials available. The Bowden tube, drive gears mounted on the frame, pushes filament through a PTFE tube.

The heater block, part of the hot end, is a thermal conductor made of aluminum. Cooling fans help dissipate heat, preventing filament melting outside the hot end. Layer fans cool filament for solidification, preventing deformation.

Endstops are vital for preventing derails and jams, ensuring smooth printing operations.

Troubleshooting Terms

To effectively troubleshoot your 3D printer, familiarize yourself with common terms like warping, heat creep, bridging, dimensional accuracy, ghosting, over-extrusion, and more. Here are some key troubleshooting terms to help you understand and address issues efficiently:

- Warping: Filament curling from print bed

- Heat Creep: Heat weakening filament prematurely

- Bridging: Filament extrusion connecting columns

- Dimensional Accuracy: Printed object size mismatch

This knowledge will enable you to diagnose problems accurately and implement targeted solutions for optimal printing results.

Common Printing Issues

Are you struggling with common printing issues on your 3D printer?

Issues like a clogged extruder, which can cause gaps or blobs in your prints, weak infill that compromises the structural integrity of your models, or stringing that leaves unwanted strands between features.

A clogged extruder occurs when debris obstructs the filament path, leading to under-extrusion or complete stops in filament flow. Gaps in prints may result from improper settings causing insufficient material deposition. Blobs and zits are excess material accumulation during printing, affecting surface quality.

Weak infill arises from inadequate infill patterns or settings, impacting the strength of your prints. Stringing, caused by excess filament oozing, can be minimized by adjusting retraction settings.

Advanced Techniques

Explore new levels of creativity and precision with advanced 3D printing techniques. Immerse yourself in these advanced methods to elevate your 3D printing skills to the next level:

- Multi-Material Printing: Combine different filaments for unique properties in a single print.

- Support-Free Printing: Utilize advanced software features to design models that require little to no support structures.

- Variable Layer Height: Adjust layer height within a single print to balance speed and detail.

- Hybrid 3D Printing: Integrate traditional manufacturing techniques with 3D printing to create hybrid models.

Industry Trends

Immerse yourself in the latest developments shaping the 3D printing landscape with a focus on Industry Trends.

As technology advances, the industry is witnessing a shift towards more sustainable practices with the introduction of eco-friendly materials like recycled filaments. Additionally, there's a growing emphasis on automation and integration of Artificial Intelligence (AI) for optimizing printing processes and reducing human intervention.

Multi-material printing capabilities are also gaining traction, enabling the creation of more complex and functional objects. Furthermore, the adoption of metal 3D printing for industrial applications is on the rise, offering superior strength and durability.

Stay updated on these trends to enhance your understanding of the evolving 3D printing industry.

Frequently Asked Questions

Can I Mix Different Types of Filaments Together for 3D Printing?

Yes, you can mix different types of filaments for 3D printing. However, it's crucial to take into account compatibility, melting points, and material properties to guarantee successful prints. Experiment cautiously to achieve desired results without causing printing issues.

How Can I Reduce the Noise Level of My 3D Printer During Operation?

To reduce the noise level of your 3D printer during operation, try placing rubber dampers under the printer, lubricating moving parts with silicone oil, and installing quieter stepper motor drivers. These simple steps can make a significant difference.

What Are the Best Practices for Storing Filament to Prevent Moisture Absorption?

To prevent moisture absorption, store filament in airtight bags with desiccants. Keep away from humid areas. Proper storage maintains print quality. Remember, moisture causes defects. Safeguard your filament investment and guarantee successful prints.

Is It Possible to 3D Print Objects With Moving Parts in One Single Print?

Yes, you can 3D print objects with moving parts in one single print. Make sure to design for interlocking components. Calibration and support settings are essential. Experiment with different orientations and consider tolerance adjustments for successful prints with moving parts.

What Safety Precautions Should Be Taken When Using High-Temperature Filaments Like Abs?

When using high-temperature filaments like ABS, make sure to have proper ventilation to mitigate toxic fumes. Always utilize a heated print bed or chamber to prevent warping. Store filament in a dry place to maintain quality. Stay safe!

Conclusion

Now that you've mastered the ultimate 3D printing glossary, you're ready to tackle any printing project with confidence. Armed with knowledge of filament types, material properties, printer parts, and troubleshooting terms, you can troubleshoot issues and achieve excellent print quality.

Stay ahead of industry trends and explore advanced techniques to take your 3D printing skills to the next level. Keep creating, innovating, and pushing the boundaries of what's possible with your newfound expertise.