When it comes to achieving peak results in 3D printing, focusing on key strength factors can truly elevate your outcomes. Imagine being able to create intricate, resilient parts that withstand the test of time. By mastering the art of infill percentage optimization, wall thickness enhancement, temperature control strategies, part orientation impact, and filament selection importance, you are on the path to realizing the full potential of 3D printing. Stay tuned to discover how these factors can revolutionize your printing success.

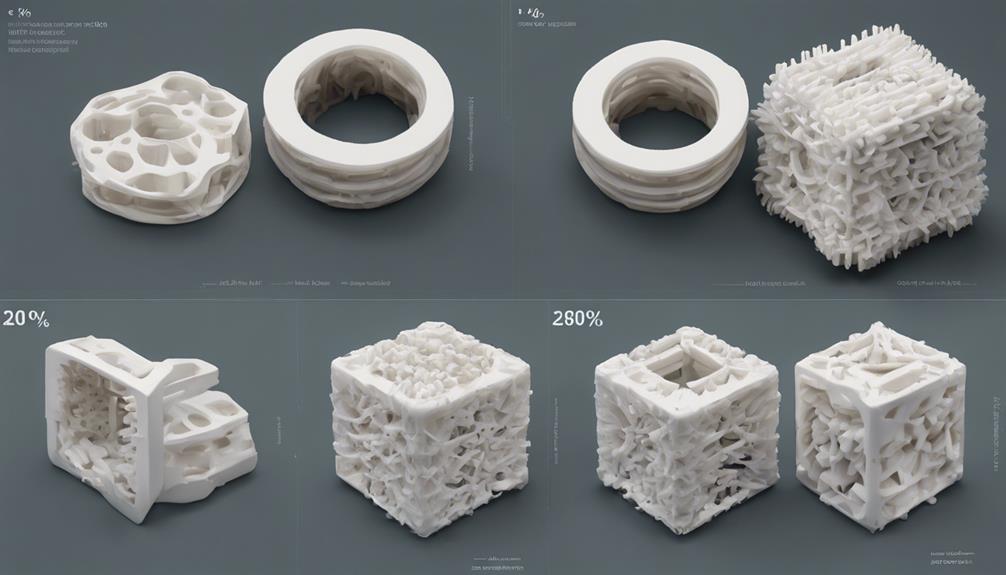

Infill Percentage Optimization

To enhance the strength of your 3D printed parts, optimizing the infill percentage is essential. Infill provides internal support, preventing collapse and increasing overall part strength. Higher infill percentages marginally boost strength but consume more filament.

Different infill patterns such as rectilinear or grid can be utilized based on your specific requirements. The infill percentage directly impacts both the quality and strength of your prints, making it a critical factor to take into account.

Ensuring the proper infill percentage aligns with the structural needs of your design is vital for achieving the desired strength in your 3D printed parts. Experimenting with various infill percentages and patterns can help you find the best balance between strength and material usage.

Wall Thickness Enhancement

Enhance the strength and durability of your 3D printed parts by optimizing the wall thickness for improved structural integrity. Increasing the wall thickness greatly contributes to the overall strength of the print. Doubling the outer wall width to 1.6mm can enhance the print's robustness.

Remember to make sure that the wall thickness is a multiple of the nozzle diameter for best results. Thicker walls not only improve print quality but also increase the durability of the printed part. Proper wall thickness plays an important role in determining the strength of your 3D printed objects.

Temperature Control Strategies

Optimizing the temperature settings is essential for ensuring proper layer adhesion and enhancing the strength of your 3D printed parts. Maintaining a consistent temperature throughout the printing process is key to achieving strong and durable prints. Fluctuations in temperature can lead to poor layer adhesion, resulting in weak parts that are prone to breaking.

Different filaments require specific temperature ranges for best performance, so be sure to adjust your settings accordingly. By closely monitoring and controlling the temperature of your 3D printer, you can improve the overall quality and strength of your prints. Remember, a stable and precise temperature environment is vital for successful 3D printing outcomes.

Part Orientation Impact

Taking into account the orientation of your 3D printed parts is crucial for maximizing their strength and durability. Parts printed in the plane parallel to the printing bed are generally stronger than those printed vertically. When designing your parts, choose a horizontal orientation to enhance strength.

Vertical prints tend to be weaker due to layer adhesion challenges and the direction of forces acting on the part. By selecting the right orientation, you can greatly impact the overall strength of your 3D prints. Remember to take into account the intended use and stress points of the part when deciding on the orientation to ensure top performance and longevity.

Filament Selection Importance

When selecting filaments for your 3D printing projects, it's essential to evaluate the impact of different filament types on the strength and quality of your final prints. The filament you choose plays a significant role in determining the durability and structural integrity of your 3D printed objects.

Factors such as filament composition, diameter, and brand can influence the overall strength of your prints. Some filaments, like ABS or PETG, provide higher strength and impact resistance compared to others like PLA.

Conduct research on various filament options and their properties to select the most suitable one for your specific printing needs. Remember, the right filament selection is key to achieving successful and robust 3D prints.

Frequently Asked Questions

How Does Infill Percentage Affect the Overall Print Strength?

When it comes to 3D printing, the infill percentage greatly influences the overall print strength. Higher infill provides internal support, enhancing strength, but consumes more filament. Choosing the right infill pattern and percentage is essential for robust prints.

What Is the Significance of Doubling Outer Wall Thickness for Print Strength?

Doubling outer wall thickness is like adding armor to your print, greatly boosting its strength. Thicker walls enhance durability and quality, ensuring a sturdy final product. Opt for this simple step to fortify your 3D prints effectively.

Why Is Optimal Temperature Crucial for Enhancing Layer Adhesion?

Maintaining ideal temperature in 3D printing is essential for enhancing layer adhesion. Proper temperatures guarantee strong bonds between layers, improving overall part strength. Without adequate heat control, weak adhesion may lead to structural weaknesses in your prints.

How Does Part Orientation Impact the Strength of 3D Printed Parts?

When considering part orientation in 3D printing, keep in mind that horizontal prints are generally stronger than vertical ones. Placing designs parallel to the printing bed provides the best strength. Make sure forces and contact directions are taken into account for the greatest results.

Why Is Selecting the Correct Filament Type Essential for Part Strength?

Choosing the appropriate filament type is essential for part strength. It impacts layer adhesion and overall durability. Opt for materials suitable for your project's requirements to guarantee the strength and quality of your 3D prints.

Conclusion

You've now mastered the secrets to 3D printing success by optimizing infill percentage, enhancing wall thickness, controlling temperature, considering part orientation, and selecting the right filament.

With these strength factors harnessed, your prints will be stronger and more reliable than ever before.

So go forth and conquer the world of 3D printing with confidence and flair! You've got this!