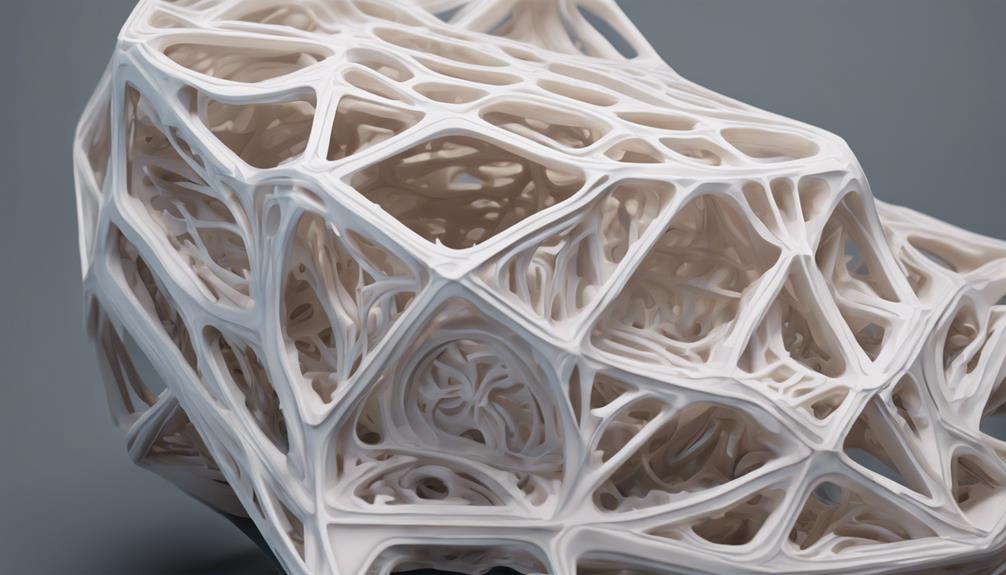

The convergence of silicone and 3D printing technologies is reshaping traditional manufacturing processes, offering a world of possibilities across industries. From intricate medical implants to customized electronics, the marriage of silicone with additive manufacturing is fueling innovative solutions. As companies pioneer advancements in material science and printing techniques, the landscape of silicone 3D printing continues to evolve, promising enhanced capabilities and applications. The synergy between these two domains holds the key to discovering new frontiers in product design and development, encapsulating a future where precision meets versatility in manufacturing.

Advantages of Silicone 3D Printing

When considering the benefits of silicone 3D printing, its non-toxic nature, thermal stability, and biocompatibility stand out as key advantages in various industries.

Silicone, being a non-toxic polymer, is safe for use in applications where contact with humans or food is a concern. Its thermal stability allows for the creation of objects that can withstand high temperatures without losing their integrity. Additionally, silicone's biocompatibility makes it a valuable material in the medical field for applications like implants and prosthetics.

These advantages position silicone 3D printing as a versatile and reliable manufacturing method for industries such as healthcare, electronics, and industrial production, where safety, durability, and compatibility are paramount.

Challenges in Silicone 3D Printing

Addressing the complexities inherent in silicone 3D printing reveals a series of formidable obstacles that manufacturers and designers must navigate to achieve successful outcomes in this innovative manufacturing process.

One of the main challenges is the high viscosity of liquid silicone, which necessitates specialized equipment and curing processes. Additionally, the availability and cost of specialized hardware and materials pose significant barriers to widespread adoption.

Unlike traditional 3D printing methods, silicone printing demands unique techniques to guarantee quality and precision. Overcoming these hurdles involves a careful balance of technology, expertise, and resources to harness the full potential of silicone 3D printing for various industries.

Innovative Applications of Silicone Printing

Exploring the complexities of silicone 3D printing challenges has paved the way for innovative applications that showcase the versatility and potential of this advanced manufacturing technology.

In the healthcare industry, silicone 3D printing is revolutionizing the production of custom medical implants and prosthetics due to silicone's biocompatibility. Dentistry benefits from silicone printing for creating precise dental prosthetics and specialized devices.

In electronics, silicone's unique properties make it an ideal material for producing components with high thermal stability and flexibility. Additionally, the industrial sector utilizes silicone 3D printing for manufacturing heat-resistant and durable parts for various applications.

These innovative uses of silicone printing underscore its adaptability and value across diverse industries.

Leading Companies in Silicone Printing

Several prominent companies are at the forefront of silicone printing technology, driving innovation and advancement in the field. ACEO, known for its pioneering work in silicone 3D printing, specializes in creating prototypes and components.

Carbon3D utilizes Digital Light Synthesis to produce wearable silicone components efficiently. EnvisionTec is recognized for its expertise in medical-grade silicone printing across diverse applications.

German RepRap focuses on aerospace and automotive applications, using silicone and polyurethane materials. Spectroplast, a Swiss company, excels in manufacturing biocompatible silicone parts through vat polymerization.

These companies showcase the diverse applications and possibilities of silicone 3D printing, catering to industries ranging from healthcare to electronics and beyond.

Future Trends in Silicone Innovation

In the domain of silicone innovation, upcoming trends are poised to revolutionize various industries.

- Enhanced Biocompatibility: Innovations in silicone formulations will improve biocompatibility for medical implants and wearable devices.

- Multi-material Printing: Advancements enabling the simultaneous printing of silicone with other materials for complex composite products.

- Increased Speed and Precision: Development of faster and more accurate 3D printing processes for intricate silicone designs.

- Customization Capabilities: Tailoring silicone properties such as elasticity and hardness to meet specific application requirements.

- Sustainable Practices: Integration of eco-friendly materials and recycling methods to reduce environmental impact in silicone production.

Frequently Asked Questions

Can Silicone 3D Printing Be Used for Food-Grade Applications?

Silicone 3D printing can be suitable for food-grade applications due to silicone's non-toxic nature and thermal stability. Specialized 3D printing processes can guarantee compliance with food safety regulations. However, guaranteeing proper material handling and testing is essential.

What Post-Processing Steps Are Required for Silicone 3D Printed Parts?

Post-processing of silicone 3D printed parts typically involves solidifying to guarantee material integrity and removing supports. Cleaning excess material, surface smoothing, and any necessary additional solidifying steps may be needed for best performance and aesthetics.

Are There Any Environmental Considerations for Silicone 3D Printing?

Environmental considerations for silicone 3D printing include the use of biocompatible and non-toxic silicone materials, reducing waste through efficient printing processes, and exploring sustainable options for silicone production. Recycling and optimizing energy usage are key aspects to address.

How Does Silicone 3D Printing Compare to Traditional Silicone Molding?

Silicone 3D printing elevates design possibilities with intricate details and complex geometries surpassing traditional silicone molding. While molding is efficient for mass production, 3D printing offers unparalleled customization and rapid prototyping capabilities.

Is It Possible to Recycle or Reuse Excess Silicone Material in 3D Printing?

Recycling excess silicone material in 3D printing is challenging due to curing processes. Reusing may require specialized equipment for material reprocessing. Sustainable practices are evolving, with limited options available currently. Collaboration for innovative solutions is key.

Conclusion

In the domain of additive manufacturing, silicone 3D printing stands as a beacon of innovation, offering a world where precision meets biocompatibility. Despite challenges, industry leaders are paving the way for a future where customized solutions and eco-friendly practices reign supreme.

Imagine a landscape where medical implants are tailored to perfection, electronics are seamlessly integrated, and industrial applications are revolutionized.

The future of silicone printing holds endless possibilities for a sustainable and personalized world.