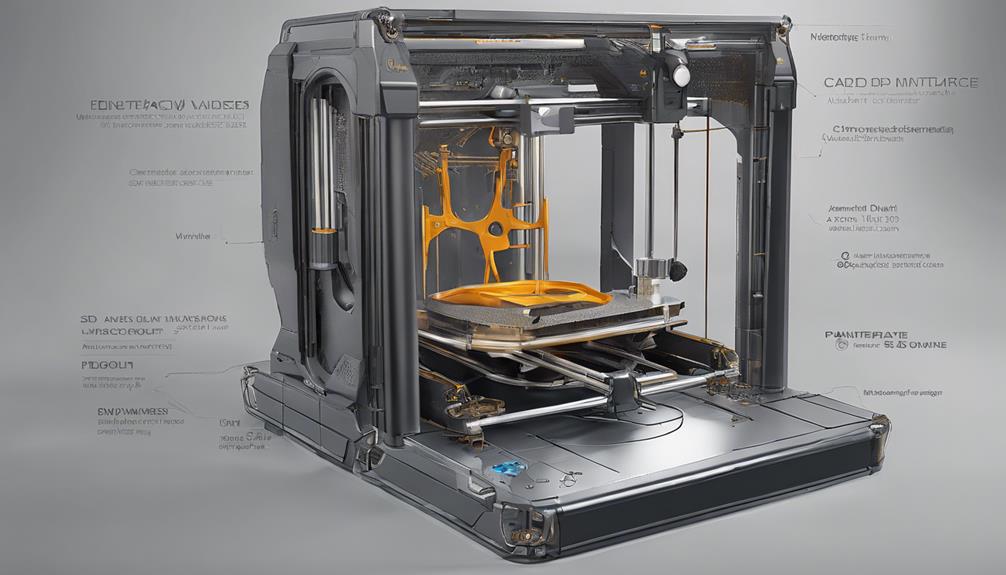

To truly enhance your 3D printing capabilities, refining your CAD creation skills is crucial. Envision the potential to bring your intricate designs to life with precision and finesse, ensuring seamless integration with the printing process. As you venture on this journey of mastering CAD creation, a world of possibilities opens before you. From selecting the ideal CAD software to optimizing design intricacies, every step you take will bring you closer to achieving unparalleled success in the domain of 3D printing.

Choosing the Right CAD Software

When selecting CAD software for 3D modeling, consider your skill level and the specific needs of your projects to guarantee the best results. If you're a beginner, user-friendly options like Tinkercad or FreeCAD may be ideal to grasp the basics.

For more complex projects, Fusion 360 offers advanced capabilities but comes with a steeper learning curve. Professionals often opt for paid software such as AutoCAD or Solidworks for intricate designs.

Accessing CAD Learning Resources

To enhance your CAD skills effectively, explore various online courses and tutorials readily available for learning CAD software. Learning from different resources can provide you with a well-rounded understanding of CAD tools and techniques.

Here are some tips to help you access CAD learning resources efficiently:

- Enroll in structured online courses offered by platforms like Coursera, Udemy, or LinkedIn Learning.

- Explore free tutorials on YouTube to grasp specific CAD concepts and workflows.

- Join online communities or forums dedicated to CAD software to seek advice and guidance from experienced users.

- Consider attending virtual workshops or webinars hosted by CAD software companies for hands-on learning experiences.

Optimizing 3D Model Designs

Explore advanced techniques to optimize your 3D model designs for successful printing.

To enhance print quality, guarantee your models have a flat base with a large surface area for better bed adhesion. Avoid steep overhangs that could lead to printing issues.

Consider the direction of layer lines to strengthen the structural integrity of your prints. Pay attention to the size of your models for dimensional accuracy.

Utilize slicing software like Ultimaker Cura to prepare your models effectively for printing.

Enhancing Bed Adhesion Techniques

Enhancing bed adhesion in your 3D printing process requires optimizing the shape and surface area of your models for improved success rates. To enhance bed adhesion techniques effectively, consider the following:

- Design with a Flat Bottom: Guarantee your models have a flat base for better adhesion.

- Increase Surface Area: Designs with a larger surface area at the bottom improve bed adhesion.

- Utilize Rafts or Brims: Adding rafts or brims can enhance bed adhesion for complex models.

- Adjust First Layer Settings: Fine-tuning the first layer settings such as bed temperature and nozzle height can improve adhesion.

Improving Print Quality and Accuracy

Improving your 3D print quality and accuracy starts with mastering the fundamentals of CAD design and understanding key printing parameters. Guarantee your designs have a flat base for better bed adhesion and consider the layer line direction for stronger prints.

Avoid steep overhangs to secure successful prints and pay attention to size for ideal dimensional accuracy. Utilize slicers like Ultimaker Cura for effective model slicing.

Enhance bed adhesion by designing models with a flat bottom and large surface area. Changing the shape of your model can also enhance adhesion, leading to higher print success rates. Manage overhangs with proper support and utilize calipers for precise measurements to achieve peak print quality.

Frequently Asked Questions

How Can I Prevent Warping in My 3D Prints?

To prevent warping in your 3D prints, maintain a level print bed, utilize a heated bed or enclosure, apply adhesion aids like glue or tape, and adjust print settings such as bed temperature and cooling fan to optimize adhesion and minimize warping.

What Are the Best Practices for Minimizing Support Material?

To minimize support material in your 3D prints, design models with self-supporting angles, gradual overhangs, and minimal need for additional supports. Orienting prints strategically can reduce the need for excessive support structures, saving time and material.

How Do I Troubleshoot Common 3D Printing Errors?

When troubleshooting common 3D printing errors, start by checking bed leveling and filament quality. Clear clogs, adjust print settings, and guarantee model orientation for best results. Regular maintenance and calibration help prevent issues, leading to successful prints.

Can I Mix Materials for Multi-Color or Multi-Material Prints?

You can mix materials for multi-color or multi-material prints. Experiment with different filament types and colors. Confirm that your printer supports this feature and follow guidelines for successful mixing to achieve unique and customized prints.

What Are the Considerations for Printing Moving Parts?

Consider printing moving parts with clearances to allow smooth motion, utilizing support structures for intricate designs, and ensuring precise measurements for proper functionality. Use slicers to optimize printing settings and test prototypes for functionality.

Conclusion

Mastering CAD creation is the key to revolutionizing your 3D printing game. Choose the right software, access learning resources, optimize your designs, enhance bed adhesion techniques, and improve print quality.

By honing your CAD skills, you can unleash endless possibilities and create intricate and precise 3D models. So, keep learning, keep practicing, and keep pushing the boundaries of what you can achieve with 3D printing.

Your journey to success starts now.