Ensuring your 3D printer nozzles are well-maintained is essential for uninterrupted printing sessions. Imagine the frustration of a clogged nozzle mid-print! By mastering the art of nozzle maintenance through simple yet effective techniques, you can save yourself from this inconvenience. From regular cleaning practices to selecting the right filament, there are key steps to follow. Explore the world of nozzle maintenance with us and discover how these practices can elevate your 3D printing experience to a whole new level.

Nozzle Cleaning Techniques

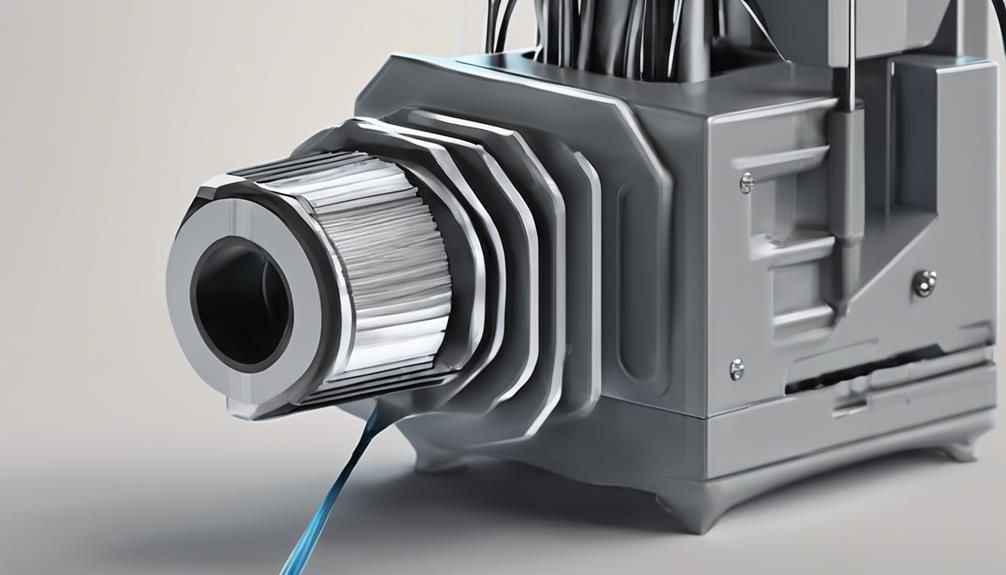

To maintain peak performance of your 3D printer, mastering effective nozzle cleaning techniques is vital. When filament residue builds up on your nozzle, it can lead to clogs and poor print quality.

Start by removing the fan shroud and silicon boot, then use a brass brush to clean the heated nozzle. Heating the nozzle before cleaning and allowing it to cool afterward guarantees thorough removal of any stuck filament.

Factors like heat creep, low printing temperature, and poor filament quality contribute to clogs, so regular cleaning is important. Remember, prevention is key; keeping your printer environment clean and choosing quality filament can help avoid nozzle clogs and keep your prints flawless.

Maintenance With Cleaning Filament

For efficient maintenance of your 3D printer, incorporating cleaning filament into your routine guarantees thorough and convenient cleaning of the nozzle.

Using cleaning filament involves preheating the nozzle, feeding the cleaning filament through, repeating the process a few times, and then switching back to your regular filament. This method is suitable for both direct drive and Bowden setup printers, offering an efficient and convenient way to keep your nozzle clean.

Preventing Nozzle Clogs

Maintain a clean environment around your printer to prevent nozzle clogs. Keeping your workspace free of dust and debris can greatly reduce the chances of clogs occurring during your 3D printing process. Additionally, using high-quality filament and avoiding prolonged preheating can help prevent impurities and blockages in your nozzle. Consider installing a filament dust filter to catch any dirt before it reaches the hotend. These simple preventive measures can go a long way in ensuring smooth and uninterrupted 3D printing sessions.

| Preventive Measure | Description | Benefit |

|---|---|---|

| Keep workspace clean | Remove dust and debris from the area | Reduce chances of clogs |

| Use quality filament | Choose high-grade filament to print with | Prevent impurities causing blockages |

| Install filament filter | Add a dust filter to catch dirt particles | Prevent debris from reaching hotend |

Clean Printer Environment

Maintaining your workspace clear of dust and debris can greatly reduce the likelihood of nozzle clogs during your 3D printing process. Dust particles in the air settle on your printer and filament, ultimately leading to clogs in the nozzle.

To uphold a clean environment, regularly dust off your printer and surrounding area. Consider using a dust filter for your filament to prevent contaminants from entering the hotend. Quality filament brands like SUNLU or Hatchbox can also contribute to a cleaner printing experience by reducing the chances of impurities causing clogs.

Filament Quality Importance

Guaranteeing high-quality filament selection is crucial for preventing nozzle clogs in your 3D printer. Opting for reputable brands like SUNLU or Hatchbox can greatly reduce the risk of impurities causing blockages. Cheaper filaments may contain inconsistencies that result in clogs during printing.

Researching and reading reviews before purchasing filament can help you make informed decisions and keep your printer running smoothly. Remember, the quality of the filament directly impacts the performance of your printer's nozzle.

Investing in good filament not only produces better prints but also minimizes the need for frequent nozzle maintenance. Prioritize filament quality to avoid frustrating clogs and ensure a more seamless 3D printing experience.

Frequently Asked Questions

How Often Should I Clean My 3D Printer Nozzle to Prevent Clogs?

To prevent clogs, clean your 3D printer nozzle regularly. The frequency depends on usage and filament type. A general rule is to clean it every 20-30 hours of printing. Consistent maintenance guarantees smooth printing.

Can Using a Dust Filter Really Help Prevent Nozzle Clogs?

Using a dust filter can work wonders in preventing nozzle clogs! It's like having a shield against the pesky filament dust invaders. Keep your printer's environment clean and enjoy smoother printing experiences with this simple yet effective solution.

What Are the Signs That Indicate My Filament Quality Is Causing Clogs?

If your prints keep jamming or look rough, your filament quality might be the culprit. Check for impurities or inconsistencies. Stick to trusted brands like SUNLU or Hatchbox to prevent nozzle clogs and guarantee smoother printing.

Is It Necessary to Clean the Nozzle if I Use High-Quality Filament?

If you use high-quality filament, it's still necessary to clean the nozzle. Residue can build up over time, affecting print quality. Regular maintenance with proper cleaning techniques guarantees top performance and prevents potential clogs.

Are There Specific Cleaning Tools or Methods to Avoid Damaging the Nozzle During Unclogging?

When unclogging, avoid damaging the nozzle using specific tools. Employ needle for blockages, cold pull for stubborn clogs. Remember to maintain filament quality, cleanliness, and suitable temperature. Prioritize prevention for smoother printing.

Conclusion

To sum up, proper maintenance of your 3D printer nozzle is essential for a smooth printing experience.

Did you know that 75% of nozzle clogs can be prevented by regularly cleaning with a brass brush?

By following simple maintenance techniques and using high-quality filament, you can avoid frustrating clogs and enjoy flawless prints every time.

Remember, a little maintenance goes a long way in mastering the art of 3D printing!