In the intricate world of 3D printing, mastering the art of warping is a skill that separates novice printers from seasoned professionals. Heated beds, often hailed as the unsung heroes in this domain, hold the key to opening up a world of possibilities for achieving flawless prints. The intricacies of temperature control, filament selection, and adhesive application are just the tip of the iceberg when it comes to tapping into the full potential of heated beds. As we explore the depths of this essential element in the printing process, a world of precision and perfection awaits those willing to venture further into the domain of mastering warping with heated beds.

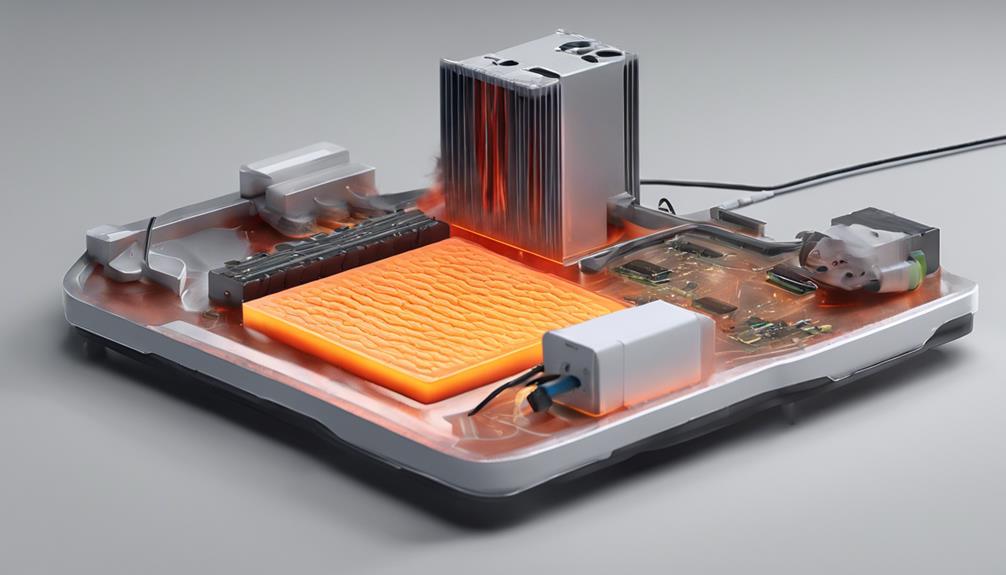

Heated Bed Technology Overview

Heated bed technology is a pivotal component in 3D printing, providing precise temperature control essential for preventing warping and ensuring excellent print quality. By maintaining a consistent temperature throughout the printing process, heated beds help the printed layers cool down uniformly, reducing the chances of warping or lifting at the edges.

This technology is especially vital when working with materials like ABS, which are prone to warping without proper temperature regulation. Additionally, heated beds contribute to better adhesion between the first layer of the print and the build surface, resulting in smoother and more accurate prints.

Filament Temperature Guidelines

What are the key factors to take into account when determining the best temperatures for different filament types in 3D printing? The temperature requirements play a vital role in achieving successful prints with various filaments. To guarantee successful results, consider the following guidelines:

- ABS Filament:

- Printing Temperature: 220-250°C

- Bed Temperature: 80-110°C

- PLA Filament:

- Printing Temperature: 180-220°C

- Bed Temperature: 20-60°C

- PETG Filament:

- Printing Temperature: 220-250°C

- Bed Temperature: 70-90°C

Adhering to these temperature ranges for specific filaments can greatly impact print quality and reduce the likelihood of warping issues.

Comparison of Heated Bed Types

Various 3D printers utilize different types of heated beds to regulate temperature during the printing process. Common types include PCB Heated Beds, known for their reliability and ease of installation, popularized by Josef Prusa's designs.

Kapton Film Heaters offer fast and uniform heating, ideal for achieving consistent print results. Aluminum Clad Heaters provide excellent heat distribution and stability, reducing the chances of warping.

Each type comes with specific features and benefits to cater to different printing needs. Understanding the characteristics and installation requirements of these heated beds is essential for optimizing print quality and minimizing warping issues.

Adhesive Solutions for Warping Prevention

For effective prevention of warping in 3D printing, utilizing appropriate adhesive solutions is essential. Adhesives play a vital role in enhancing bed adhesion and reducing the chances of warping.

Here are three essential adhesive solutions for warping prevention:

- Painter's Tape: Commonly used for its ease of application and removal. It provides a smooth surface for the first layer to adhere to, reducing the likelihood of warping.

- Kapton Tape: Known for its heat resistance and ability to create a strong bond between the print and the bed, especially useful for printing materials like ABS that require higher bed temperatures.

- Hairsprays and Glues: These can be effective in promoting adhesion between the print and the bed, particularly for materials that tend to warp easily.

Expert Recommendations and Insights

To further enhance the effectiveness of adhesive solutions in preventing warping during 3D printing, expert recommendations and insights provide valuable guidance for optimizing print quality and bed adhesion. Experts suggest ensuring the heated bed is level to aid in proper adhesion.

Adjusting the nozzle height is important, with recommendations often suggesting a distance slightly closer than the standard paper thickness. Using a heated bed at the correct temperature for the specific filament being used is also essential.

Additionally, experts advise experimenting with different adhesives to find the most suitable one for the chosen material. By following these expert recommendations, 3D printing enthusiasts can greatly improve their printing outcomes and reduce the likelihood of warping issues.

Frequently Asked Questions

How Can I Determine the Right Temperature Settings for My Specific Filament?

To determine the right temperature settings for your specific filament, refer to manufacturer guidelines, perform calibration prints, and adjust temperatures in increments for best adhesion and print quality. Understanding filament properties is key to successful 3D printing.

What Are the Common Mistakes That Can Lead to Warping, Even With a Heated Bed?

Common mistakes leading to warping despite a heated bed include inadequate bed leveling, insufficient bed adhesion, rapid cooling due to drafty environments, improper filament temperature settings, and inadequate part cooling. Ensuring proper calibration and environmental conditions is essential.

Is It Necessary to Constantly Monitor the Heated Bed Temperature During Printing?

Monitoring the heated bed temperature during printing is essential for ensuring consistent heat distribution, filament adhesion, and preventing warping. Regular temperature checks help maintain print quality and prevent issues related to uneven cooling.

Can Using a Heated Bed Improve the Overall Strength and Durability of 3D Prints?

Utilizing a heated bed can greatly enhance the strength and durability of 3D prints by ensuring ideal adhesion and reducing warping. Proper temperature control promotes layer adhesion, resulting in structurally sound prints suitable for various applications.

Are There Any Alternative Methods to Prevent Warping if a Heated Bed Is Not Available?

In the absence of a heated bed, alternative methods to prevent warping include adjusting print settings, using adhesives for better bed adhesion, enclosing the printer to maintain temperature, and selecting suitable filaments that are less prone to warping.

Conclusion

In summary, mastering the use of heated beds in 3D printing is essential for achieving high-quality prints.

By understanding filament temperature guidelines, choosing the right heated bed type, and utilizing adhesive solutions for warping prevention, users can greatly improve their printing outcomes.

Remember, 'a stitch in time saves nine,' emphasizing the importance of proactive measures to prevent warping and guarantee successful prints.