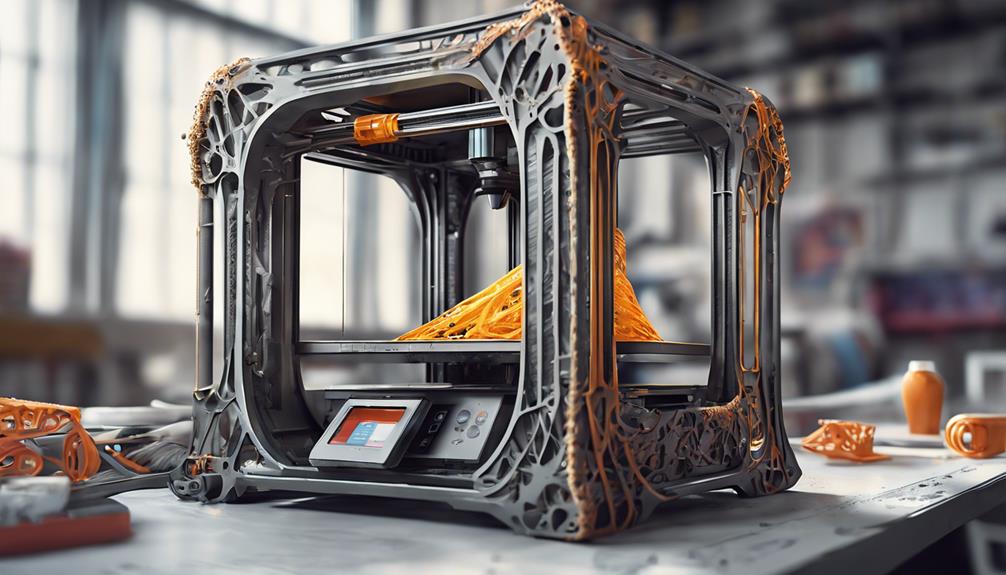

As 3D printing enthusiasts, we grasp that dealing with supports can sometimes feel like a tedious and complex task. However, mastering the art of 3D printing supports is essential to achieving flawless prints. By honing our skills in support placement, overhang management, and advanced support techniques, we can unveil a world of possibilities in creating intricate and high-quality designs. Join us as we uncover the secrets to perfecting 3D printing supports, leading to enhanced printing outcomes and pushing the boundaries of what is possible in the world of 3D printing.

Understanding the Basics of Supports

Understanding supports in 3D printing is vital for ensuring successful print outcomes. Supports prevent filament extrusion into the air and support overhangs and bridges. They play a pivotal role in maintaining the structural integrity of intricate designs during the printing process.

These supports are intelligently placed by slicing software to provide stability where needed most. Adjusting support settings can enhance the overall finish of the print, ensuring a smoother and more accurate outcome. Additionally, manual support placement offers extra flexibility for specific requirements.

Necessity and Optimization Strategies

To guarantee successful 3D printing outcomes, mastering the importance and optimization strategies for supports is essential.

Understanding the critical parameters and the impact of printer variations on support requirements is vital. Overhang limits are determined by angles and distances, with experience leading to more efficient support placement.

It's evident that supports play a key role in achieving high-quality prints. By starting with basic settings and gradually adjusting based on individual printer characteristics, one can optimize support usage.

Recognizing the significance of supports in ensuring print success is fundamental.

As we explore further into managing overhangs and bridges, these optimization strategies will prove invaluable in enhancing the overall 3D printing experience.

Managing Overhangs and Bridges

Exploring effective techniques for optimizing overhangs and bridges enhances the success of 3D printing projects. When managing overhangs and bridges, attention to detail is key. Here are some tips to help you navigate this important aspect of 3D printing:

- Ensuring proper support placement boosts print quality and stability.

- Fine-tuning overhang angles can prevent sagging and improve overall aesthetics.

- Implementing ideal bridging settings enhances structural integrity.

- Conducting test prints with varying parameters refines your approach.

- Experimenting with cooling methods can greatly impact overhang and bridge performance.

Improving Support Structures

Managing overhangs and bridges effectively sets the foundation for enhancing support structures in 3D printing projects. For improved support structures, ensuring that at least half of the filament width is supported is essential for stability. Keeping overhang angles under 45° typically yields better results, but adjusting parameters can push this limit further.

Experimenting with various print settings and cooling methods helps optimize overhangs and bridges. Testing with overhang prints allows for fine-tuning adjustments to achieve the best outcomes. By understanding the impact of different parameters on support structures and actively refining these settings, we can enhance the overall quality of 3D prints, ensuring successful outcomes with minimal waste of materials.

Exploring Advanced Support Techniques

Advanced techniques in 3D printing support structures offer innovative solutions for optimizing print quality and efficiency.

- Embracing these techniques can elevate our printing capabilities.

- Learning new methods can be both challenging and rewarding.

- Experimenting with different support types can lead to surprising results.

- Pushing the boundaries of what's familiar can spark creativity and innovation.

- Mastering advanced support techniques opens doors to endless possibilities in 3D printing.

Frequently Asked Questions

Can Supports Be Reused for Multiple Prints?

Yes, supports can be reused for multiple prints depending on their condition. We inspect supports after each print for damage or wear. If supports are intact and effective, we reutilize them to minimize material waste and printing costs.

How Do Supports Impact Print Speed?

Supports impact print speed by increasing it due to the additional material and time required for support structures. Adjusting support settings can help balance quality and speed. We found that optimizing supports is essential for efficient printing.

Are There Supports Specifically for Flexible Filaments?

Yes, there are supports designed for flexible filaments. They provide stability during printing and aid in achieving intricate designs. Adjusting settings is important for successful results. Experimentation helps in finding the ideal support configuration.

Can Supports Be Adjusted During a Print?

We can't magically tweak supports mid-print, but adjusting them on-the-fly would be revolutionary! Our dream scenario? Real-time support optimization tools for seamless adjustments and perfect prints, making us 3D printing wizards!

What Is the Impact of Support Removal on Print Quality?

Removing supports impacts print quality by affecting surface finish and structural integrity. We must carefully remove supports to avoid damaging the print. Cleaning up supports post-print guarantees a smooth final product, enhancing the overall quality of our prints.

Conclusion

So, to sum up, by mastering 3D printing supports, we reveal the key to unleashing the full potential of our prints. Through trial and error, we push the boundaries of what's possible and challenge ourselves to create more intricate and innovative designs.

The truth is, with dedication and perseverance, we can achieve remarkable results that elevate our 3D printing skills to new heights. Keep exploring, keep experimenting, and keep pushing the limits of what you thought was possible.