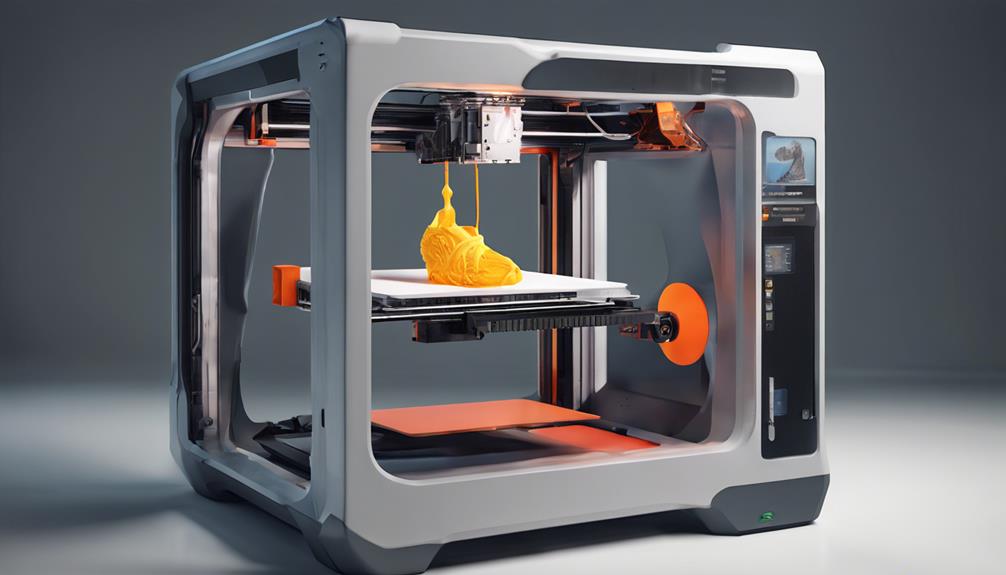

Addressing layer skipping issues in your 3D printer is vital for achieving consistent and high-quality prints. When layers are skipped, the structural integrity of your prints can be compromised, resulting in a subpar outcome. By focusing on regular maintenance tasks and fine-tuning various settings, you can troubleshoot and potentially resolve these issues. Stay tuned to discover effective strategies and tips to rectify layer skipping woes and optimize your 3D printing endeavors.

Identifying Layer Skipping Symptoms

Identification of layer skipping symptoms is essential for diagnosing and resolving issues affecting 3D print quality. Signs of layer skipping may manifest as gaps or missing layers in the printed object, resulting in a fragile structure.

Additionally, irregular material flow during printing and a lack of proper adhesion between layers can indicate this problem. Conducting a visual inspection of the print can help identify these irregularities, while capturing images for closer examination can assist in accurately pinpointing the issue.

Mechanical Maintenance Tips

Proper mechanical maintenance is essential to guarantee the smooth operation and longevity of your 3D printer. Regular upkeep of your printer's mechanical components can help prevent issues like layer skipping.

Make sure all nuts and screws are tightened to maintain structural integrity. Check for any misaligned rods or supports that could lead to printing inaccuracies. It is also vital to keep the nozzle unclogged for consistent extrusion.

Slicer Settings and Calibration

To guarantee peak performance and print quality on your 3D printer, meticulous attention to slicer settings and calibration is essential. Adjusting the flow rate for proper extrusion and modifying resolution for better print quality are key adjustments that can be made.

It is vital to check and adjust retraction settings, cooling settings, and ensure filament compatibility. Slicing software parameters need to be set correctly to achieve peak performance.

Proper calibration of these settings can greatly impact the overall print quality and help prevent layer skipping issues. By fine-tuning these settings and ensuring precise calibration, you can enhance the performance and output of your 3D printer.

Uncommon Causes of Layer Skipping

Rarely encountered but remarkable, several lesser-known factors can contribute to the occurrence of layer skipping in 3D printing processes. A warped print bed can lead to uneven printing surfaces, causing layers to skip.

Issues with the extruder gear, such as wear or misalignment, may disrupt the filament feeding process, resulting in skipped layers. Incorrect filament diameter settings can also impact extrusion consistency, leading to layer inconsistencies.

Additionally, improper spool alignment can create tension variations in the filament, causing disruptions in layer deposition. Checking the condition of the PTFE tube and toothed wheel for any damage or blockages is vital to ensure smooth filament flow and prevent layer skipping in 3D prints.

Troubleshooting and Recommendations

When encountering layer skipping issues on your 3D printer, thorough troubleshooting and implementing recommendations are essential for peak printing performance. Here are some key steps to help you resolve these issues effectively:

- Check Mechanical Components: Confirm all nuts, screws, rods, and supports are properly tightened and aligned.

- Review Slicer Settings: Adjust flow rate, resolution, retraction, cooling, and filament compatibility settings for best performance.

- Inspect Uncommon Causes: Look for issues like a warped bed, extruder gear problems, incorrect filament diameter, and spool alignment.

- Follow Additional Recommendations: Consider installing an automatic leveling sensor, maintaining proper extruder gear tension, regular cleaning of nozzle clogs, and consistent bed calibration for improved printing results.

Frequently Asked Questions

Can Software Updates Fix Layer Skipping Issues?

Software updates may offer improvements in print quality and performance but may not directly fix layer skipping issues. Mechanical maintenance, proper calibration, and troubleshooting uncommon causes are crucial. Follow manufacturer recommendations for best results.

Is Lubricating Moving Parts Necessary for Prevention?

'An ounce of prevention is worth a pound of cure. Lubricating moving parts in a 3D printer is essential for smooth operation, reducing friction, and preventing wear. Regular maintenance guarantees top performance and can help prevent layer skipping issues.'

How Often Should Belts Be Checked for Tension?

Belts should be checked for tension regularly, ideally every 3-6 months or whenever visible signs of wear, slippage, or misalignment occur. Correct tension guarantees peak printer performance, smooth movement, and precise print outcomes.

Does Filament Age Affect Layer Skipping Occurrence?

As time passes, filament undergoes aging changes affecting its integrity and flow consistency, potentially contributing to layer skipping. Monitoring filament storage conditions and expiry dates, and ensuring the best filament quality can help mitigate such issues.

Can Using Different Slicing Software Prevent Layer Skipping?

Using different slicing software can potentially prevent layer skipping by optimizing settings for your specific printer. Adjusting parameters like flow rate, retraction, and resolution accurately in the new software may resolve issues related to layer skipping.

Conclusion

In summary, addressing layer skipping issues with your 3D printer is essential for top-notch print quality. By identifying symptoms, performing mechanical maintenance, adjusting slicer settings, and troubleshooting uncommon causes, you can enhance your printing experience.

Remember, prevention is key to avoiding fragile structures and ensuring smooth, high-quality prints. Stay diligent in your maintenance efforts to keep your printer running smoothly and producing flawless creations.