Experiencing layer separation issues in your 3D prints can be a frustrating setback, causing imperfections that compromise your projects. Knowing how to prevent and remedy this common problem is crucial for achieving high-quality prints consistently. By implementing specific strategies and adjustments, you can greatly reduce the occurrence of layer separation and guarantee smoother printing outcomes. Stay tuned to uncover practical tips and solutions that will elevate your 3D printing experience and help you achieve flawless results effortlessly.

Understanding Layer Separation

If you're encountering layer separation issues in your FDM 3D prints, understanding the causes and factors behind weak layer adhesion is essential for troubleshooting and prevention.

Layer delamination or separation is a common problem that can result in cracked or split prints. Factors like cooling contraction in materials such as ABS can contribute to this issue. When forces exceed adhesion strength, prints can crack, but this is preventable with proper precautions.

Cooling rates, warping, and adhesion all play critical roles in layer separation. By grasping the reasons behind weak layer adhesion, you can take proactive steps to address these issues and enhance the quality of your 3D prints.

Causes and Prevention

To prevent layer separation in your FDM 3D prints, understanding the causes and taking proactive measures is essential. Cracking can occur due to uneven cooling rates and warping forces impacting the print. Simple steps like managing cooling and ensuring proper adhesion can help prevent layer separation.

Factors such as plastic cooling at different rates and inadequate bed temperature maintenance can lead to issues. By adjusting settings like bed temperature and monitoring cooling rates, you can mitigate the risk of layer separation. Ensuring the correct adhesion between layers and managing cooling effectively are key in preventing cracks and delamination.

Paying attention to these factors can greatly improve the quality of your 3D prints and reduce the chances of layer separation.

Solutions for Layer Separation

For addressing layer separation in your FDM 3D prints, consider implementing effective solutions to enhance print quality. Improve layer adhesion by adjusting settings like lowering the layer height and increasing printing temperature. These adjustments enhance the contact surface and bond strength between layers, reducing the likelihood of separation.

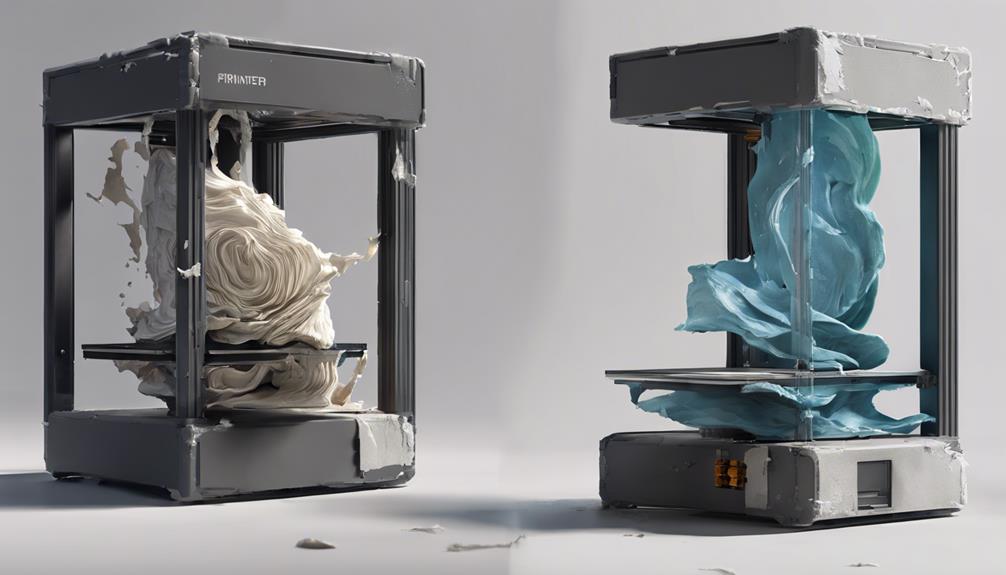

Additionally, utilizing an enclosure can help stabilize the internal temperature of the printer, preventing uneven cooling and warping issues. Enclosures can be purchased or DIY constructed to suit your needs.

Utilizing Enclosures for Better Printing

Consider using an enclosure to stabilize your printer's internal temperature and prevent warping issues for better 3D printing results. Enclosures offer a simple yet effective solution to maintain consistent printing conditions. Here are some tips to help you make the most of using enclosures:

- Enclosures provide a controlled environment for your printer.

- DIY enclosures can be tailored to fit your specific requirements.

- They can be purchased pre-made or constructed from scratch.

- Enclosures help prevent uneven cooling, reducing the risk of warping.

Additional Tips

Check your nozzle for clogging regularly to guarantee top printing quality and avoid weak prints due to under-extrusion. Clogs can disrupt the extrusion process, leading to incomplete layers and poor adhesion.

To address this, consider using a nozzle cleaning kit or performing a cold pull method to clear any obstructions. Additionally, keep filament dry and dust-free to prevent clogs from forming.

Regular maintenance will secure smooth extrusion and consistent layer adhesion, reducing the risk of layer separation issues. By staying proactive with your printer care, you can maintain peak performance and minimize the chances of encountering printing defects related to nozzle clogging.

Frequently Asked Questions

Can Using a Hairdryer Help in Preventing Layer Separation?

Using a hairdryer won't prevent layer separation effectively. You should focus on managing cooling rates, adhesion, and bed temperature. Simple steps like adjusting settings and using enclosures are more beneficial in preventing layer separation issues.

Are There Specific Filaments More Prone to Layer Separation?

Are specific filaments more prone to layer separation? Yes, certain materials like ABS can be more susceptible due to cooling contraction. However, adjusting printing conditions and using proper techniques can help prevent this issue effectively.

Is It Necessary to Recalibrate the Printer After Fixing Layer Separation?

After fixing layer separation, recalibration may not always be necessary. Monitor print quality closely; if issues persist, consider recalibrating. Adjust settings as needed for best results. Regular maintenance and troubleshooting can help maintain consistent print quality.

How Can Humidity Affect Layer Adhesion in 3D Printing?

Humidity can impact layer adhesion in 3D printing by causing moisture absorption in filament, leading to weak bonds. Manage humidity levels in your printing environment to prevent issues. Control moisture for better adhesion.

Can Applying a Post-Print Adhesive Help Strengthen Weak Layers?

Applying a post-print adhesive can help strengthen weak layers in 3D prints. It enhances layer adhesion, reducing the risk of delamination. Follow instructions carefully, ensuring proper application for best results. Strengthen your prints easily with this effective solution.

Conclusion

To sum it up, managing cooling rates, ensuring proper adhesion, and utilizing enclosures are key in preventing and fixing layer separation in FDM 3D prints.

Remember, regular maintenance is essential to maintain consistent layer adhesion.

Did you know that by maintaining proper nozzle temperature and adjusting settings, you can reduce the risk of layer separation by up to 80%?

Keep these tips in mind for successful 3D printing projects!