In the domain of 3D printing, the debate between Delta and Cartesian printers continues to intrigue enthusiasts and professionals alike. Each type comes armed with distinct advantages and limitations, creating a dichotomy between speed and quality that is at the heart of this ongoing discussion. While Delta printers boast rapid vertical precision, their ability to deliver intricate horizontal details remains a point of contention. Conversely, Cartesian printers are renowned for their impeccable print quality but at the cost of reduced speed. To navigate this battleground of printers effectively, one must carefully weigh the project requirements against the desired outcome, ensuring a judicious choice that aligns with the specific needs at hand.

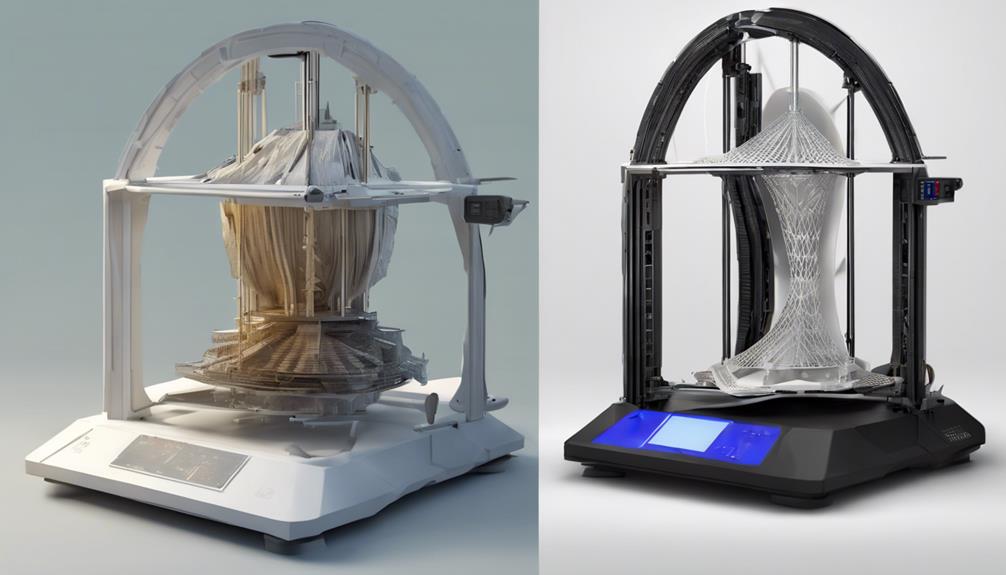

Delta and Cartesian Printer Overview

In comparing Delta and Cartesian 3D printers, it is essential to understand their fundamental differences in design and operation. Delta printers utilize three arms for movement on a round print bed, enabling fast printing with accurate vertical precision. However, they may struggle with achieving high detail and finish on final products, especially in larger horizontal prints.

On the other hand, Cartesian printers operate on an X, Y, and Z coordinate system with a square moving print bed. Despite being slower, Cartesian printers excel in producing high-quality prints with smooth finishes. They are user-friendly, offer support for various filament types, and are generally easier to set up and maintain compared to Delta printers.

Each type has its own strengths and limitations, catering to different user preferences and printing needs.

Performance Comparison: Speed Vs Quality

When evaluating the performance of Delta and Cartesian 3D printers, a critical aspect to mull over is the balance between printing speed and print quality. Here are three key points to ponder:

- Speed: Delta printers typically offer faster printing speeds due to their lightweight print heads and reduced moving parts, making them suitable for projects that require quick turnaround times.

- Quality: Cartesian printers are known for producing high-quality prints with smooth finishes, making them ideal for intricate designs and detailed models where precision is paramount.

- Balance: Choosing between speed and quality depends on the specific requirements of the project. While Delta printers excel in speed, Cartesian printers prioritize print quality, offering a trade-off that users must contemplate based on their printing needs.

Pros and Cons of Delta Printers

Considering the advantages and disadvantages of Delta printers provides insights into their unique characteristics in the field of 3D printing technology.

Delta printers are known for their fast printing speeds, enabled by reduced inertia and lightweight print heads. This results in quick vertical printing with efficient use of print space.

However, Delta printers often struggle with achieving high levels of detail and finish on final products, making them less suitable for intricate designs. Additionally, these printers face limitations when it comes to producing large horizontal-sized prints.

Despite their speed advantages, Delta printers can be more complex and challenging to troubleshoot compared to Cartesian printers, which offer easier maintenance and higher print quality at the expense of speed.

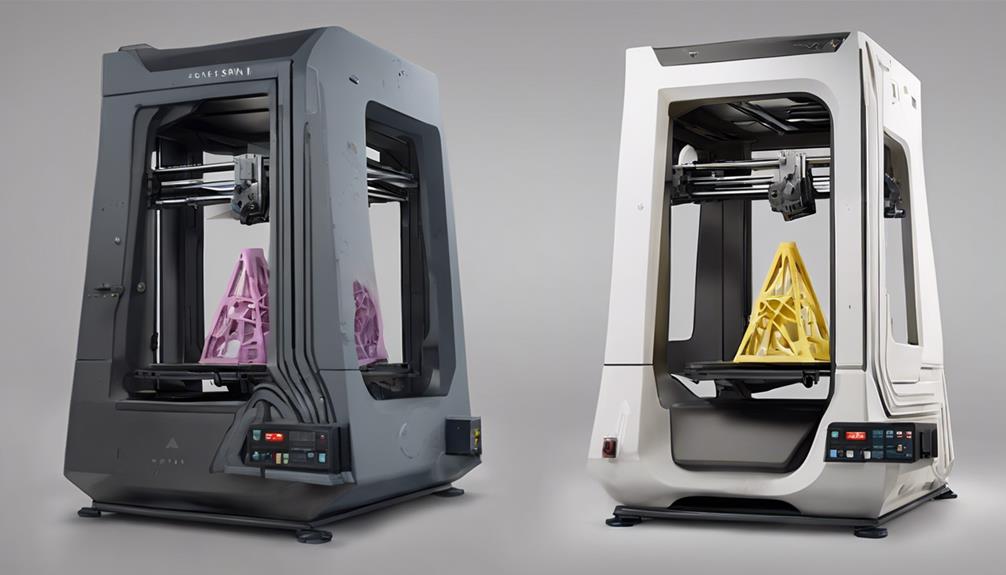

Pros and Cons of Cartesian Printers

Within the domain of 3D printing technology, Cartesian printers exhibit distinct advantages and disadvantages that shape their performance and usability in various applications.

Pros of Cartesian Printers:

- User-Friendly: Cartesian printers are known for their ease of use, making them suitable for beginners and experienced users alike.

- High-Quality Prints: Despite being slower than Delta printers, Cartesian printers produce high-quality prints with smooth finishes.

- Affordability and Versatility: Cartesian printers are often more affordable than Delta printers and support a wide range of filament types, making them versatile for different printing needs.

Factors to Consider When Choosing

Moving forward from the discussion on the pros and cons of Cartesian printers, an informed decision on selecting between Delta and Cartesian printers necessitates a careful evaluation of specific factors. When choosing between Delta and Cartesian printers, consider the following factors:

| Factor | Delta Printers | Cartesian Printers |

|---|---|---|

| Print Speed | Faster due to reduced inertia and improved response time | Slower due to heavier moving parts |

| Print Quality | May have poorer detail and finish on final products | Produces high-quality prints with smooth finishes despite being slower |

| Setup Ease | More complex setup and troubleshooting compared to Cartesian printers | Easier to set up initially |

| Print Bed Shape | Round print bed | Square print bed |

Evaluate these factors based on your printing needs and priorities to make an informed decision between Delta and Cartesian printers.

Frequently Asked Questions

Can Delta Printers Produce Larger Prints Than Cartesian Printers?

Delta printers, with their round print beds and vertical printing capabilities, are more suitable for taller prints but may have limitations in producing large horizontal prints compared to Cartesian printers. Each type offers distinct advantages based on print requirements.

What Are the Main Differences in Maintenance Between Delta and Cartesian Printers?

Delta printers, with their three-arm design and round print beds, differ from Cartesian printers, which operate on X, Y, and Z coordinates with a square print bed. Delta printers may require more intricate maintenance due to their complex structure compared to Cartesian printers.

Are There Any Specific Software Requirements for Delta or Cartesian Printers?

When considering software requirements for 3D printers, both Delta and Cartesian printers can generally utilize common slicing software such as Cura, Simplify3D, or PrusaSlicer. Compatibility with specific firmware and printer settings may vary.

Do Delta Printers Have Any Advantages in Terms of Energy Efficiency?

Innovative design elements in Delta printers contribute to enhanced energy efficiency. Their utilization of three arms for swift movements, reduced inertia, and lightweight print heads result in optimized energy consumption, setting them apart in the field of 3D printing technology.

Can Cartesian Printers Be Modified to Match the Speed of Delta Printers?

While Cartesian printers can be modified with upgrades such as lightweight print heads and optimized settings to increase print speed, achieving the same level of speed as Delta printers may pose challenges due to their inherently different design and operational mechanisms.

Conclusion

In the domain of 3D printing, the debate between Delta and Cartesian printers rages on. While Delta printers offer rapid printing speeds, Cartesian printers boast superior print quality.

When selecting between the two, it is crucial to take into account project requirements and priorities. Whether prioritizing speed or quality, the decision ultimately hinges on finding the perfect balance between efficiency and precision.

Choose wisely, as the battle of printers continues to shape the future of 3D printing technology.