When it comes to bonding 3D prints, the choice of glue can make all the difference in ensuring your project's success. From Acrylic Cement to Hot Glue Guns, each adhesive offers unique benefits and properties tailored to different filament types. So, if you're looking to create durable and reliable bonds in your 3D prints, understanding the characteristics of each glue option is essential.

Acrylic Cement (WeldOn 16)

When bonding your 3D prints, Acrylic Cement (WeldOn 16) proves to be a reliable choice for materials like ABS, PLA, or PETG due to its strong adhesive properties. This cement creates a robust bond between your printed parts, ensuring a durable and long-lasting connection.

To use Acrylic Cement effectively, make sure to clean the surfaces with alcohol and sand any uneven areas flat before applying the adhesive. Additionally, remember to take necessary safety precautions as Acrylic Cement contains Methylene Chloride, making it highly flammable and toxic.

Super Glue (Gorilla Super Glue)

For guaranteeing your 3D prints effectively, consider using Gorilla Super Glue, known for its ideal adhesion properties with materials like ABS, PLA, or PETG. This super glue offers a fast curing time, making it a convenient choice for quick projects.

To use it, start by sanding the surfaces you plan to bond, then clean them thoroughly with alcohol to secure a strong adhesion. Avoid any dirt or grease on the surfaces. Keep in mind that Gorilla Super Glue can irritate your airways and eyes if inhaled, so work in a well-ventilated area.

When applied correctly, this super glue provides a reliable and durable bond for your 3D prints.

Acetone (Klean-Strip)

To effectively bond ABS, HIPS, PLA, or acetone-dissolvable materials in your 3D prints, consider utilizing Acetone from Klean-Strip. Acetone works by partially dissolving the outer layer of the 3D print, creating a strong bond when the parts are pressed together.

To use Acetone for bonding, lightly sand the surfaces to be joined, apply a small amount of Acetone, and press the parts together firmly. Allow time for the Acetone to evaporate and the bond to set properly.

Remember to work in a well-ventilated area and wear protective gloves to avoid direct contact with the chemical. Acetone is flammable and evaporates quickly, so take necessary precautions to guarantee safety during use.

Contact Cement (Girukka OVC)

Considering the effectiveness of Acetone for bonding certain 3D print materials, now let's shift our focus to Contact Cement (Girukka OVC) and its application in bonding ABS, HIPS, and PLA filaments. Contact Cement is solvent-based and requires minimal surface preparation. Apply a small amount to the bonding surfaces, then hold them together using duct tape or clamps until fully cured. Here's a comparison table to highlight the key aspects of Contact Cement:

| Contact Cement (Girukka OVC) | |

|---|---|

| Suitable Filaments | ABS, HIPS, PLA |

| Surface Preparation | Minimal |

| Application Method | Apply, hold, cure |

| Safety Precautions | Similar to acetone |

Epoxy

When considering bonding 3D printed objects, Epoxy offers versatility and effective adhesion for various filament types. Epoxy provides a strong bond suitable for most filament materials, except for flexible ones.

It's ideal for projects where durability is key, as it can withstand moderate stress. Although Epoxy may not offer the highest bonding strength compared to super glue or acrylic cement, its ability to fill gaps and create secure connections makes it a valuable adhesive for a wide range of applications.

Remember to work in a well-ventilated area when using Epoxy and avoid high-stress applications where a more robust adhesive might be necessary.

Hot Glue Gun

For bonding 3D printed objects, the Hot Glue Gun is a popular choice due to its strong bonding capability with rigid materials like ABS and PLA. The Hot Glue Gun provides effective bonding for rigid filaments and offers a quick and easy application process. It's suitable for various projects and dries quickly.

However, it's important to avoid skin contact with the hot glue to prevent potential burns. This method of bonding requires clean surfaces for best adhesion but may leave visible marks on the prints. Overall, the Hot Glue Gun is a convenient and efficient option for bonding 3D printed objects made from ABS and PLA materials.

Thermal Welding

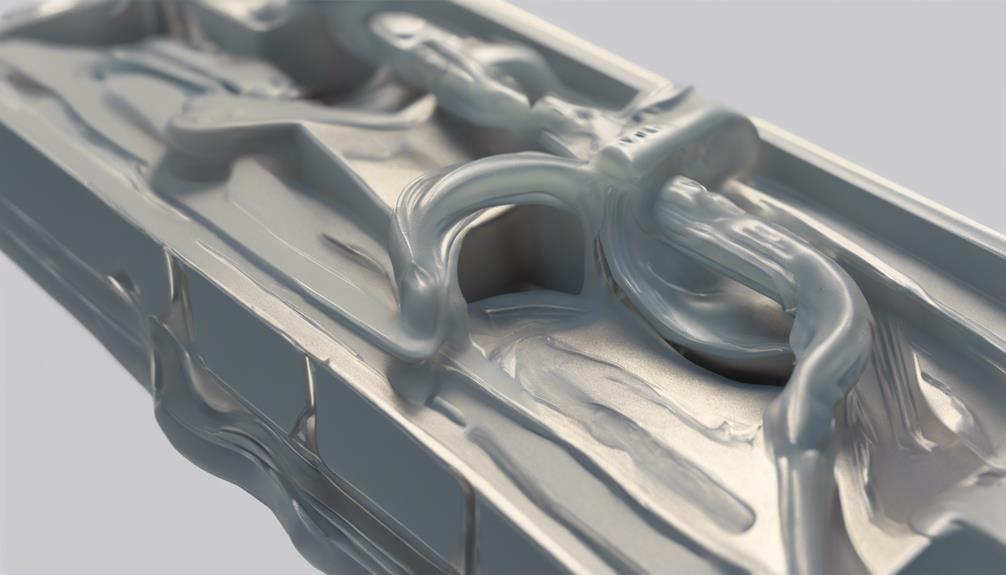

Thermal welding is a friction welding technique that provides durable bonds in 3D printed pieces. To achieve this, a rotary tool generates heat to fuse parts together in layers.

For seamless joints, post-processing with sandpaper and polishing is recommended. The quality of the bond can be affected by the drill speed used during the welding process.

Thermal welding offers a strong and lasting connection between 3D printed components, ensuring structural integrity and stability. This technique is particularly useful for creating robust and functional objects that require reliable adhesion between layers.

Experimenting with different speeds and refining your welding skills can lead to improved results and stronger bonds in your 3D printed creations.

Frequently Asked Questions

Can I Use These Glues on Flexible 3D Printing Filaments?

You can't use these glues on flexible 3D printing filaments due to their weak bonding with such materials. Opt for specialized adhesives like flexible resin or glue specially designed for flexible filaments for better results.

How Long Does Each Glue Take to Fully Cure?

When using different glues to bond 3D prints, consider the curing time of each. Be patient as you wait for the adhesive to fully cure. Rushing this process may compromise the strength of the bond.

Are These Glues Suitable for Outdoor Applications?

For outdoor applications, consider factors like UV exposure, temperature changes, and moisture resistance. Acrylic cement, super glue, and epoxy are suitable choices, but make sure proper surface preparation and application for long-lasting bonds in outdoor environments.

Can These Glues Be Painted Over Once Dried?

Once dried, these glues can be painted over, enhancing your 3D prints' appearance. Make sure adequate drying time and use appropriate paints for different glue types. Experiment with colors to personalize your creations further.

Do These Glues Work on 3D Prints With Textured Surfaces?

Yes, these glues can bond textured surfaces on 3D prints. Sanding and cleaning the surface is essential for effective adhesion. Make sure to maintain proper ventilation and safety precautions due to the flammable and toxic nature of some glues.

Conclusion

To sum up, selecting the right glue is crucial for strong and durable bonds when working with 3D prints.

Did you know that over 80% of 3D printing enthusiasts recommend using Acrylic Cement like WeldOn 16 for their bonding needs?

By choosing the appropriate adhesive for your specific filament type, you can guarantee secure connections and successful projects every time.

So, remember to pick the right glue for your 3D printing needs and create lasting bonds with confidence!