Imagine a world where vehicles are not just a means of transportation but personalized works of art. The introduction of 3D printing has sparked a significant shift in the automotive manufacturing industry. This cutting-edge technology has not only transformed the way cars are built but has opened up a domain of possibilities for customization and innovation. As you explore the impact of 3D printing on the automotive sector, you will uncover how it is reshaping the industry's landscape and paving the way for a new era of automotive design and production.

Advantages of 3D Printing in Automotive Manufacturing

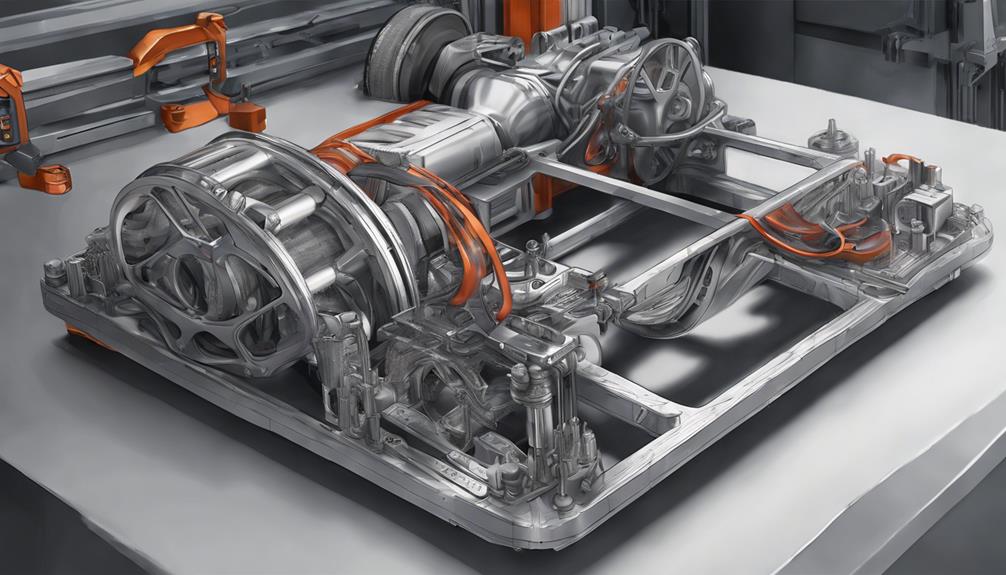

3D printing in automotive manufacturing offers unparalleled flexibility and efficiency in producing complex and customized car parts. This technology allows for the creation of intricate designs that traditional manufacturing methods struggle to achieve. With 3D printing, car manufacturers can easily produce prototypes and even final parts with reduced lead times.

The ability to customize parts according to specific requirements enhances the overall design and functionality of vehicles. Companies like BMW and Volkswagen have embraced 3D printing to accelerate their innovation process and offer unique solutions to consumers. By integrating additive manufacturing into their production processes, automotive manufacturers can stay ahead in a competitive market while meeting the increasing demand for personalized products.

Impact on Production Efficiency

Enhancing production efficiency in the automotive industry through the integration of 3D printing technologies has become an essential strategy for major manufacturers. By utilizing 3D printing, companies can streamline their production processes, reduce material waste, and improve overall operational effectiveness. This technology allows for rapid prototyping, on-demand manufacturing of spare parts, and the creation of complex geometries that were previously challenging to produce. Below is a table highlighting the key benefits of 3D printing on production efficiency:

| Benefits of 3D Printing in Production Efficiency |

|---|

| Rapid Prototyping |

| On-Demand Spare Parts Manufacturing |

| Complex Geometries Production |

| Reduced Material Waste |

| Improved Operational Effectiveness |

Customization Opportunities With 3D Printing

Discover a world of personalized possibilities in automotive design and accessories with the revolutionary capabilities of 3D printing.

With 3D printing, you can customize car parts and accessories to suit your unique preferences and requirements. Whether it's a custom-designed dashboard, personalized door handles, or bespoke emblems, 3D printing enables you to tailor your vehicle to reflect your individual style.

Explore the freedom to create one-of-a-kind features that stand out on the road and showcase your personality. From intricate details to functional add-ons, the customization opportunities with 3D printing are endless.

Embrace this innovative technology to transform your car into a personalized masterpiece that sets you apart from the rest.

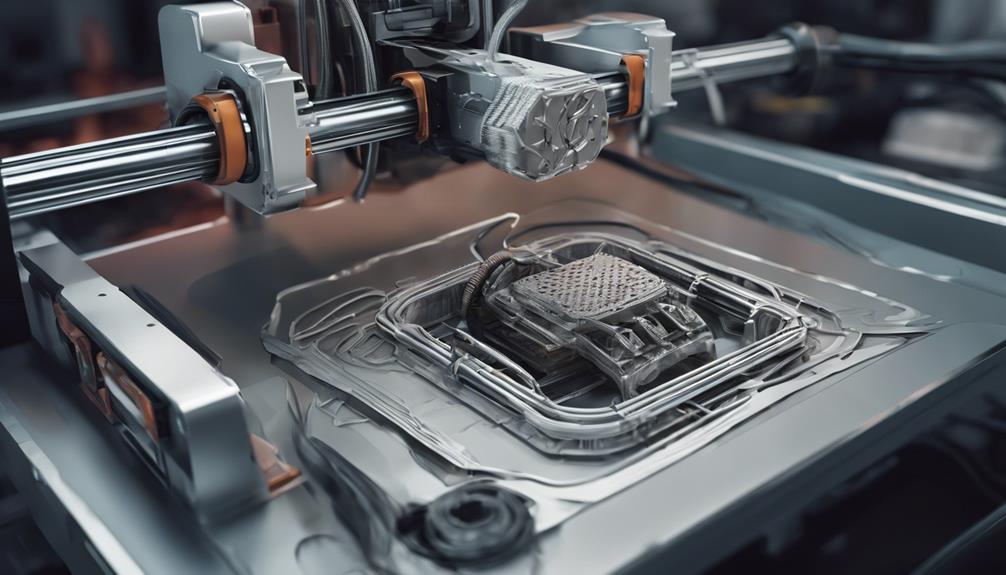

Role of 3D Printing in Prototyping

Incorporating additive manufacturing techniques into the prototyping process can greatly streamline development in the automotive industry.

By utilizing 3D printing for prototyping, car manufacturers can rapidly iterate designs, test functionality, and assess performance before moving into full-scale production. This approach saves time and resources compared to traditional prototyping methods, allowing for quicker innovation cycles and improved product quality.

Additive manufacturing enables the creation of complex geometries and customized parts with ease, providing designers and engineers the flexibility to experiment and refine their ideas efficiently.

Companies that integrate 3D printing into their prototyping workflows benefit from reduced lead times, enhanced design validation, and overall cost savings, ultimately driving advancements in the automotive sector.

3D Printing Driving Innovation in Automotive Industry

3D printing revolutionizes the automotive industry by driving innovation through advanced manufacturing techniques. This technology allows for the production of intricate and customized car parts, leading to enhanced design possibilities and improved efficiency in production processes.

Major car manufacturers like BMW and Volkswagen are utilizing 3D printing for prototyping and creating complex components. Additive manufacturing accelerates the design iteration process, enabling companies to offer extensive customization options to consumers.

Frequently Asked Questions

Can 3D Printing in Automotive Manufacturing Lead to Reduced Material Waste?

In automotive manufacturing, 3D printing can lead to reduced material waste by precisely creating parts. This technology enables customization and efficient prototyping, minimizing excess material usage. Embrace 3D printing for sustainable practices and streamlined production processes.

How Does 3D Printing Impact the Supply Chain in the Automotive Industry?

When considering how 3D printing impacts the supply chain in the automotive industry, it streamlines production, accelerates prototyping, and offers tailored solutions. Incorporating this technology enhances efficiency, flexibility, and customization in manufacturing processes.

What Are the Limitations of Customization With 3D Printing for Car Parts?

When customizing car parts with 3D printing, limitations arise in size constraints and material choices. Understanding these constraints helps optimize designs for effective functionality. Choose materials wisely to guarantee durability and performance in your creations.

How Does 3D Printing Accelerate the Prototyping Process in Automotive Design?

3D printing speeds up automotive prototyping by allowing quick design iterations. Choose suitable filaments like ABS for durability. Customized parts are achievable, but expertise is essential. 3D printing enhances testing phases for safer and efficient production.

What Safety Standards Must 3D Printed Car Parts Meet for Mass Production?

To guarantee safe mass production, 3D printed car parts must meet stringent safety standards. Adhering to regulations is essential for vehicle integrity. Testing for durability and impact resistance is mandatory before integrating these parts into manufacturing processes.

Conclusion

You've seen how 3D printing is transforming the automotive industry, offering unmatched flexibility and customization. But you might be wondering about the cost.

Don't worry, as the technology advances, the cost of 3D printing is steadily decreasing, making it a more cost-effective option for manufacturers.

Embrace the future of automotive manufacturing with 3D printing and stay ahead of the competition.