As you explore the domain of 3D printing, understanding the intricate network of costs involved is paramount. From the initial investment in hardware to ongoing material expenses and operational considerations, the landscape can be intricate. However, by unraveling the mysteries behind these costs, you can gain a clear understanding of how to manage your budget effectively. Through this detailed guide, you will uncover invaluable insights that can empower you to make informed decisions and optimize your 3D printing endeavors with confidence.

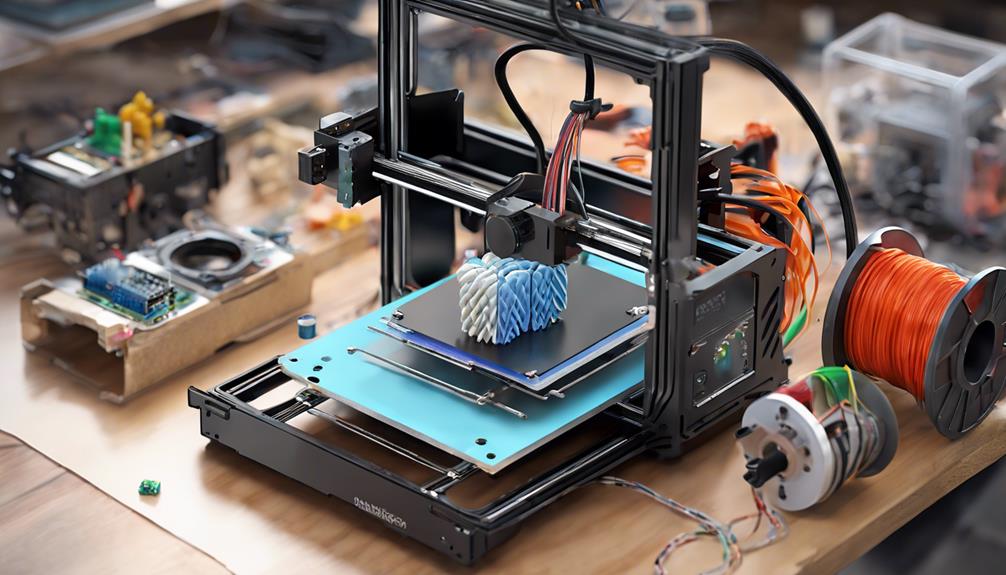

3D Printer Hardware Costs

When considering 3D printer hardware costs, it's essential to evaluate the initial investment required for the specific type of printer you're interested in.

DIY printer kits are the most budget-friendly option, typically costing around $200. Hobbyist printers range from $500 to $1,500, offering more features and reliability.

If you're looking for professional-grade FDM printers, be prepared to start at $2,500 for standard models and $4,000 for large-format ones. For those interested in SLA desktop printers, prices usually start at $3,500.

Understanding the initial investment needed for different types of printers will help you make an informed decision based on your budget and printing requirements.

Printing Technology and Material Expenses

Understanding the printing technology and material expenses is crucial for accurately estimating the overall costs of 3D printing. FDM printers utilize molten filament layers for a mechanical bond, while SLA printers use lasers to cure resin for a chemical bond.

Filament costs typically amount to around $20 per 1Kg spool of materials like PLA, ABS, or PETG. Resin costs range from $15 to $45 for a 500ml volume.

Keep in mind factors like material waste and additional elements needed for printing when calculating expenses. These costs, in addition to the choice of printing technology, play a significant role in determining the total cost of your 3D printing projects.

Operating Costs and Maintenance Considerations

To effectively manage your 3D printing expenses, carefully assess and plan for operating costs and maintenance requirements. Operating costs encompass electricity expenses, which average 12.69 cents per kWh in North America.

Proper maintenance is crucial to prevent downtime and part replacements. This includes regular tasks like cleaning nozzles and replacing worn-out components. Neglecting maintenance can lead to reduced print quality and higher repair costs in the long run.

Be proactive in monitoring your printer's condition and addressing any issues promptly. By staying on top of maintenance and factoring in operating costs, you can optimize the efficiency and longevity of your 3D printer while keeping expenses in check.

Software and Design Expenses

Considering the significance of software and design expenses in 3D printing, it's essential to carefully evaluate the costs associated with CAD and slicer software to effectively manage your budget. CAD software prices vary, with options like Autodesk Fusion 360 offering free licenses for hobbyists and small businesses.

Slicer software, such as Cura or PrusaSlicer, is generally free but can impact print quality and speed. It's important to factor in any additional design software costs if needed for specific projects. While some online repositories offer free design files, custom designs or modifications may incur extra expenses.

Understanding these software costs upfront will help you make informed decisions and optimize your 3D printing budget.

Cost Optimization Strategies and Outsourcing Options

Now, let's explore effective ways to optimize costs and consider outsourcing options in 3D printing.

To optimize costs, adjust slicer settings such as supports, infill density, and print speed. These factors directly impact the amount of material used and printing time, affecting overall expenses. Additionally, leveraging economies of scale by increasing print quantities can reduce the cost per part.

When it comes to outsourcing, consider tapping into industrial 3D printing services for access to high-quality prints without the upfront investment in expensive equipment. While outsourcing may incur higher costs for one-time prints, it can be a cost-effective solution for specialized or large-scale projects where quality is paramount.

Evaluate your printing needs to determine the most cost-efficient approach for your specific requirements.

Frequently Asked Questions

Can I Use Different Materials in the Same Print Job?

Yes, you can use different materials in the same print job. It offers versatility for unique creations. Guarantee compatibility between materials to avoid printing issues. Experiment with combinations for customized and functional 3D prints.

Are There Any Hidden Costs Associated With 3D Printing?

When 3D printing, hidden costs like material waste, electricity, and maintenance impact your expenses. Consider optimizing settings, outsourcing for industrial printers, and accounting for software and design fees. Proper maintenance is key to cost control.

How Do Different Slicer Software Options Impact Costs?

When choosing slicer software, consider how it's like picking the right tool for a job – Simplify3D may cost $150 but offers precise control, while free options like Cura suit basic needs.

What Is the Average Lifespan of a 3D Printer?

When considering the average lifespan of a 3D printer, factors like maintenance, usage frequency, and quality of components play a role. Generally, with proper care, a well-maintained 3D printer can last several years, providing longevity for your projects.

Is It More Cost-Effective to Buy or Lease a 3D Printer?

When deciding between buying or leasing a 3D printer, consider factors like frequency of use, budget, and long-term goals. Purchasing may be more cost-effective if you plan on regular use and customization.

Conclusion

To sum up, maneuvering through the world of 3D printing costs can be challenging, but with careful consideration and strategic planning, you can manage your budget effectively.

By understanding the hardware, material, operating, and software expenses, as well as exploring cost optimization strategies and outsourcing options, you can make informed decisions to maximize your resources.

Remember, staying informed and proactive is key to demystifying 3D printing costs and achieving your printing goals with ease.