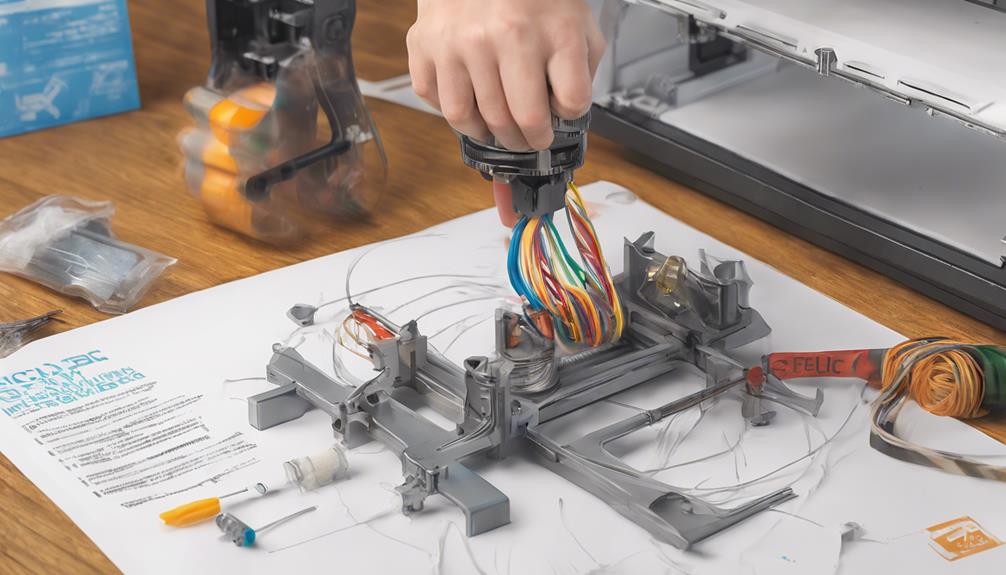

If you find that your 3D printer is struggling with filament feed issues, such as inconsistent extrusion or nozzle clogs, addressing these issues promptly is crucial. By understanding the common culprits behind these problems, like worn-out drive gears or improper filament storage, you can troubleshoot effectively and improve your printing experience. Stay tuned to discover practical tips and techniques to overcome these challenges and optimize your 3D printing results.

Identifying Common Filament Feed Issues

If you're experiencing problems with your 3D printer filament feed, understanding the important causes is essential for troubleshooting effectively. Issues such as a clogged extrusion path, damaged PTFE tube, incorrect retraction settings, improper filament tension, or inaccurate extruder temperature can all lead to feed problems.

By identifying these significant causes, you can take targeted actions to address the issue at hand. Checking for clogs, ensuring proper filament alignment, adjusting retraction settings, and verifying temperature settings are all vital steps in resolving filament feed issues.

Troubleshooting Feed Problems Effectively

To effectively address filament feed problems with your 3D printer, pinpointing the specific troubleshooting steps is crucial for resolving issues efficiently.

When troubleshooting, start by checking for a worn-out drive gear, a clogged nozzle, incorrect printing temperatures, dust and dirt in the filament, or the nozzle being too close to the print bed. These issues can often lead to feeding problems.

By systematically identifying and addressing these common culprits, you can quickly get your printer back up and running smoothly. Remember to follow manufacturer guidelines for maintenance and adjustments.

If problems persist, consider seeking professional assistance to make sure your printer operates at its best capacity.

Importance of Filament Quality and Maintenance

Ensuring top-notch filament and appropriate maintenance practices are essential for peak performance and longevity of your 3D printer. Here's why it matters:

- Quality Filament: Using high-grade filament reduces the risk of clogs and ensures consistent prints.

- Regular Maintenance: Routine upkeep, such as cleaning the extruder and checking for any wear and tear, helps prevent issues before they arise.

- Proper Storage: Storing filament in a dry and dust-free environment prolongs its lifespan and maintains print quality.

Various Nozzle Unclogging Techniques

When dealing with nozzle clogs in your 3D printer, employing effective unclogging techniques is essential for maintaining peak printing performance. Start by using a brass wire brush to gently scrub away any debris on the nozzle.

Another method is to feed cleaning filament through the nozzle to push out any blockages. You can also try manually pushing filament through the nozzle to dislodge the clog.

For more stubborn clogs, consider using a guitar string or needle to carefully clear the blockage. Lastly, the atomic or cold pull technique involves heating the nozzle and then quickly pulling out the filament to remove any obstructions.

Exploring Advanced Nozzle Unclogging Methods

Explore more advanced techniques to effectively unclog your 3D printer's nozzle, ensuring peak printing performance and maintenance.

- Unblock partially clogged nozzle: Use a combination of cleaning filament and manual pushing to remove partial clogs efficiently.

- Unblock fully clogged nozzle: Employ techniques like atomic or cold pulls to clear stubborn clogs completely.

- Use of specific materials for cleaning: Consider using specialized cleaning filament or brass wire brushes for targeted nozzle maintenance.

These methods go beyond basic unclogging techniques and can help tackle more severe obstructions, ensuring smoother printing processes and extending the lifespan of your 3D printer's nozzle.

Frequently Asked Questions

How Can I Prevent Filament From Getting Tangled During Printing?

To prevent filament tangling during printing, make sure spools rotate freely, use filament guides, and monitor spool movement. Maintain proper tension and avoid sudden movements. Secure loose ends and check filament path for obstructions. Regularly inspect and adjust for smooth feeding.

Is It Normal for the Filament to Make Popping Sounds?

It's not unusual for filament to make popping sounds during printing. This could indicate moisture in the filament causing steam pockets. Guarantee proper filament storage and consider using a dehydrator to maintain ideal printing conditions.

Can Changing the Extruder Speed Affect Filament Feeding?

Adjusting the extruder speed can impact filament feeding by influencing the rate at which filament is pushed through. Verify that the speed aligns with your filament type and printer settings to avoid feeding issues and uphold print quality.

What Impact Does Humidity Have on Filament Feeding?

Humidity affects filament feeding by causing moisture absorption, leading to clogs and poor print quality. Store filament in a dry place and consider using a dehumidifier. Regularly check and maintain your printer to prevent issues.

How Often Should I Clean the Extruder Gears for Optimal Performance?

For peak performance, clean your extruder gears every 300-500 printing hours. Regular maintenance prevents clogs and guarantees smooth filament feeding. Stay proactive in keeping your gears debris-free for consistent 3D printing quality.

Conclusion

Don't let filament feed problems slow you down. Identify, troubleshoot, and maintain for smooth 3D printing.

Quality filament, proper storage, and nozzle care are key. Keep printing smoothly and efficiently with these tips.