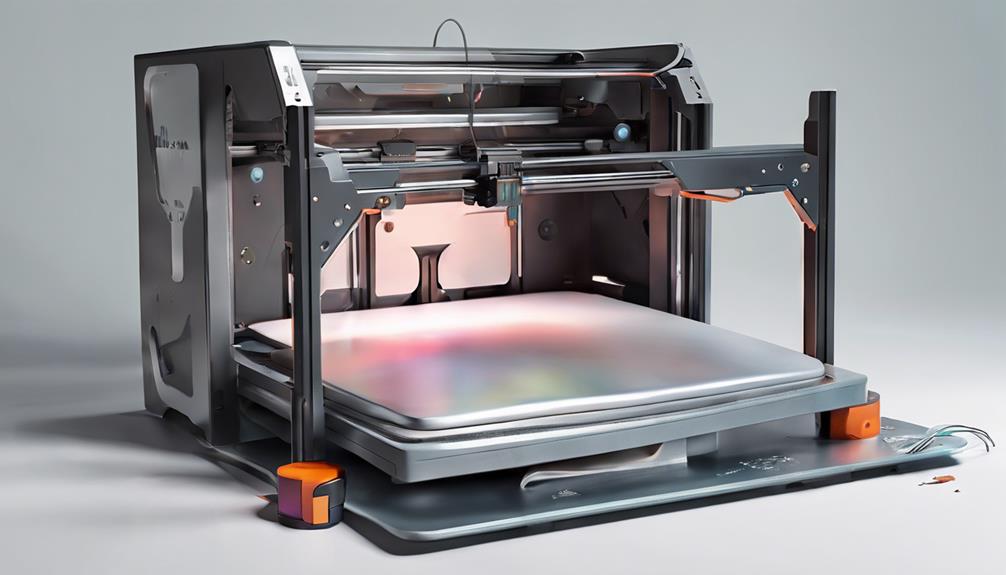

Exploring the world of 3D printing bed materials reveals a maze of choices, each bearing distinct advantages and drawbacks. As the foundation upon which your creations take form, selecting the best bed material is a crucial decision in ensuring successful prints. From the reliable heat distribution of aluminum to the durability of glass and the convenience of magnetic beds, each option beckons with promises and pitfalls. The nuances of these bed materials are intertwined with your printing journey, influencing outcomes and efficiency. Delve into this guide to uncover the secrets that will elevate your 3D printing endeavors to new heights.

Aluminum Bed Overview

In the domain of 3D printing, the aluminum bed stands out for its exceptional heat distribution and retention capabilities. This material offers fast heat absorption and even distribution, essential for successful prints.

Despite being lightweight, aluminum beds can suffer from warping when not properly maintained. Users often need to apply glue stick or hairspray to enhance adhesion, which can diminish over time with frequent use.

With a price range typically falling between $15-$40, aluminum beds are an affordable option for many hobbyist 3D printers. While they may require more frequent replacement compared to other bed materials, the benefits of consistent heat distribution and cost-effectiveness make aluminum beds a popular choice in the 3D printing community.

Glass Bed Characteristics

Continuing the exploration of bed materials in 3D printing, the characteristics of glass beds offer ideal thermal shock resistance and a smooth, even surface, making them a popular choice among hobbyist 3D printer users.

Glass beds, typically made of borosilicate glass, are known for their durability and ability to withstand high temperatures up to 240 degrees Celsius. While they may require additional adhesion aids like glue sticks or hairspray, glass beds are less prone to warping compared to aluminum beds.

However, they are susceptible to cracking if not handled carefully. With an excellent thickness of 3-4mm for most hobbyist 3D printers, glass beds provide a reliable printing surface that is easy to clean and maintain.

Magnetic Bed Considerations

When considering 3D printing bed materials, the utilization of magnetic beds presents unique advantages and considerations for users seeking efficient print adhesion and removal. Magnetic beds offer great adhesion without the need for additional adhesives, making them ideal for PLA filament due to their easy print removal process.

However, it is important to note that magnetic beds require more heat due to their added mass and may need to be replaced more frequently compared to other bed materials. Various types of magnetic beds are available in the market, such as Build Tak FlexiPlate and Easy-Peelzy, offering users options to suit their specific printing needs.

Magnetic beds, while convenient for print release, may suffer from durability issues and warping over time, potentially leading to higher replacement costs.

Pros and Cons of Bed Materials

Considering the selection of 3D printing bed materials, it is essential to weigh the advantages and disadvantages of different options to determine the most suitable choice for your printing needs.

Aluminum beds offer even heat distribution and are cost-effective but are prone to warping and require frequent replacement.

Glass beds, though affordable and durable, can be slow to heat up and are prone to cracking.

Magnetic beds provide easy print release and cleaning but may warp over time and require costly replacements.

Each material has its strengths and limitations, so choosing the right bed material depends on factors like budget, printing requirements, and maintenance capabilities.

Usage and Maintenance Tips

To guarantee peak performance and longevity of 3D printing bed materials, diligent attention to proper usage and maintenance is essential. For aluminum beds, be cautious of warping caused by excessive heat on thin plates, and regularly check for warping when warmed up. Cleaning adhesive residues off aluminum beds should be done carefully to prevent scratching.

Glass beds, particularly those made of borosilicate glass, can withstand temperatures up to 240 degrees Celsius. Make sure the glass bed has a suitable thickness for your printer size, as inferior quality glass may not endure thermal shock.

Magnetic beds consist of two flexible sheets, one adhesive and one magnetic, and require frequent replacement due to the degradation of magnetic properties over time.

Recommendations and Alternatives

Drawing from the insights and experiences shared on 3D printing bed materials, the recommended products section offers valuable suggestions for enhanced printing outcomes.

Build Tak is highly recommended for an improved printing experience, known for its reliable adhesion properties.

Glass beds stand out as a popular choice among users, providing a smooth and durable printing surface with high satisfaction rates.

Another viable option is an aluminum build plate with a glass overlay, combining the benefits of both materials.

To address adhesion issues, the use of a glue stick or hairspray can effectively enhance print adhesion on various bed materials.

These recommendations aim to optimize the 3D printing process and promote successful print outcomes.

Additional Information and Insights

Within the domain of 3D printing bed materials, exploring additional information and insights reveals essential details for optimizing printing processes and enhancing print outcomes.

Understanding the nuances of different bed materials can have a substantial impact on the quality of prints produced. Factors such as heat distribution, adhesion properties, durability, and maintenance requirements play important roles in selecting the most suitable bed material for specific printing needs.

Additionally, insights from experienced users can provide valuable tips and recommendations for overcoming common challenges associated with different bed materials.

Frequently Asked Questions

Can I Use a Glass Bed With a Magnetic Build Surface?

Using a glass bed with a magnetic build surface is feasible. The glass provides a smooth and durable printing surface, while the magnetic sheet enhances adhesion and print removal. Verify compatibility and proper installation to maximize benefits.

How Do I Prevent Warping on an Aluminum Bed?

To prevent warping on an aluminum bed, make sure proper bed leveling and use a heating bed with a consistent temperature. Avoid sudden cooling and consider using a heated enclosure. Regular maintenance checks for any signs of warping can help preserve the bed's flatness.

Are There Any Special Cleaning Tips for Magnetic Beds?

Special cleaning tips for magnetic beds include using a mild detergent and warm water to gently clean the surface. Avoid harsh chemicals that can damage the magnetic properties. Regular maintenance, such as wiping with a microfiber cloth, helps prolong the bed's lifespan.

Can I Mix and Match Different Bed Materials on My 3D Printer?

Mixing and matching different bed materials on a 3D printer is feasible but may necessitate adjustments for compatibility. Guarantee proper leveling and adhesion techniques are utilized. Experiment cautiously to balance heat distribution, adhesion, and durability for ideal printing results.

What Is the Optimal Bed Temperature for Different Materials?

The ideal bed temperature for different materials varies: Aluminum beds perform well at 60-70°C, glass beds around 40-60°C, and magnetic beds between 50-70°C. Adhering to these temperatures enhances adhesion and prevents issues like warping or poor print quality.

Conclusion

In summary, selecting the right 3D printing bed material is essential for successful printing outcomes.

As the saying goes, 'Different strokes for different folks,' each material offers unique strengths and limitations that cater to specific printing needs and budgets.

By understanding the characteristics, pros, and cons of aluminum, glass, and magnetic beds, along with following proper maintenance tips, users can achieve peak performance and quality prints in their 3D printing projects.