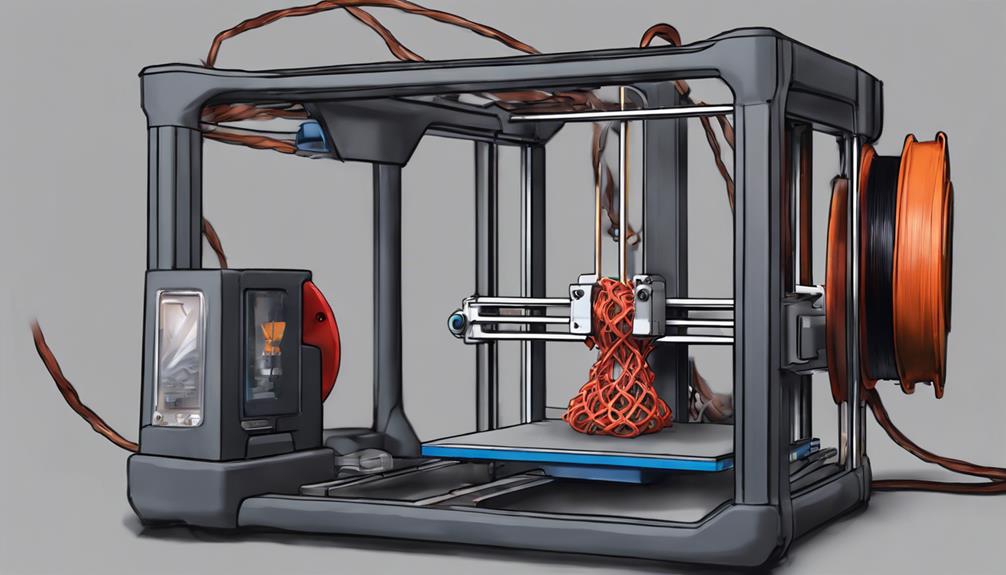

Extruder jams can be a real headache for 3D printer enthusiasts, disrupting your printing process and causing frustration. But fear not, as there are simple solutions to tackle this issue and get your printer back on track. From basic maintenance tasks to fine-tuning settings, a few adjustments can make a world of difference in your printing quality. By addressing these common problems head-on, you can save yourself time and hassle, ensuring your 3D printing projects proceed smoothly and successfully.

Common Causes of Extruder Jams

If you're experiencing extruder jams on your 3D printer, common causes could include filament tangling, nozzle clogs, or overheated extruder motor drivers.

Filament tangling can occur due to improper spooling or handling of the filament, leading to blockages in the extruder.

Nozzle clogs often happen when debris or melted filament accumulates inside the nozzle, obstructing the filament flow.

Overheated extruder motor drivers can result from prolonged use or high printing speeds, causing the extruder to stop functioning correctly.

Effective Troubleshooting Techniques

When troubleshooting extruder jams on your 3D printer, implementing effective techniques can swiftly resolve issues and guarantee smooth printing operations. Begin by checking the spool to confirm filament availability. Estimate filament consumption to avoid unexpected stoppages.

Installing a filament runout sensor can prevent mid-print filament depletion. Prevent filament tangling by using proper spool holders. Adjust the nozzle height to guarantee proper filament flow. Check and adjust the printing temperature as needed for different filaments. Always use quality tested materials to prevent clogs.

Clear any dust accumulation in the room to maintain a clean printing environment. If a clog occurs, manually push filament to unclog or heat the hot end to clear obstructions. Employ methods like the Atomic or Cold Pull methods for deeper cleaning when necessary.

Essential Preventative Maintenance Tips

Implement these essential preventative maintenance tips to ensure the longevity and peak performance of your 3D printer.

- Regularly clean the extruder and hotend to prevent buildup

- Check and tighten belts, screws, and other components for proper alignment

- Lubricate moving parts such as rods and bearings to reduce friction

- Calibrate the printer bed and nozzle height for best printing quality

Key Takeaways for 3D Printing Success

For successful 3D printing outcomes, prioritize regular maintenance and adhere to best practices. To guarantee your 3D printer operates at its peak, follow these key takeaways:

| Key Takeaways | Description |

|---|---|

| Regular Maintenance | Clean the nozzle and check for clogs regularly to prevent extruder jams. |

| Quality Filament | Use high-quality filament to avoid clogs and ensure smooth printing. |

| Monitor Hotend Fan | Confirm the hotend fan is clean and functioning properly for best prints. |

| Replace PTFE Tube if Needed | Monitor the PTFE tube condition and upgrade to a higher temperature one if necessary. |

Bonus Cleaning and Maintenance Hacks

To enhance the longevity and efficiency of your 3D printer, consider incorporating these clever cleaning and maintenance hacks.

- Use a stainless steel needle, fine wire, or guitar string to clean the nozzle

- Regularly check and clean the printer's cooling fans to prevent overheating

- Keep your print bed level and clean to guarantee proper adhesion

- Lubricate moving parts such as rods and belts to reduce friction and wear

Frequently Asked Questions

Can Using Low-Quality Filament Cause Extruder Jams?

Using low-quality filament can cause extruder jams. Make sure you use good quality filament to prevent clogs and maintain smooth printing. Remember, regular maintenance and using quality materials are key to a trouble-free 3D printing experience.

How Often Should the PTFE Tube Be Replaced?

Regularly check the PTFE tube condition to prevent extruder issues. Replace it when signs of wear appear, such as deformation or discoloration. Maintaining a healthy PTFE tube guarantees smooth filament flow and excellent 3D printing performance.

Is It Normal for the Extruder Motor Driver to Overheat?

If your extruder motor driver overheats, it might indicate a problem. Make sure proper ventilation and check for obstructions. Consider upgrading cooling solutions if necessary. Keeping your printer cool helps prevent issues and ensures smooth printing.

Can Dust Accumulation in the Room Affect 3D Printing?

Dust accumulation in the room can impact 3D printing by causing clogs and affecting print quality. Keep your workspace clean to prevent issues. Regular maintenance and cleanliness are essential for best printing results and the longevity of your printer.

What Is the Atomic Method for Unclogging Extruders?

If you've ever pondered the atomic method for unclogging extruders, immerse yourself in its precision. Heat, pull, and watch the residue dance away. Marvel at the magic of 3D printing maintenance. Plunge in!

Conclusion

So, you've learned all about preventing and fixing those pesky extruder jams. Now you can sit back and relax, right?

Wrong! 3D printing is a constant game of maintenance and troubleshooting. But hey, at least now you have the tools to handle whatever jams come your way.

Happy printing!