Have you ever wondered that up to 40% of 3D printer failures are related to cooling fan issues? Understanding how to troubleshoot your 3D printer's cooling fan can save you time and frustration. By mastering a few simple techniques, you can easily diagnose and fix common problems that may arise with your cooling fan. Stay tuned to discover straightforward solutions to guarantee your 3D printer's cooling system operates smoothly and efficiently.

Common Causes of Cooling Fan Malfunction

When troubleshooting cooling fan issues on your 3D printer, identifying common causes of malfunction is crucial for effective resolution. The printing parameters set in the Slicer software could be causing the fan to malfunction. Confirm that the machine configuration aligns with the fan requirements to prevent any issues.

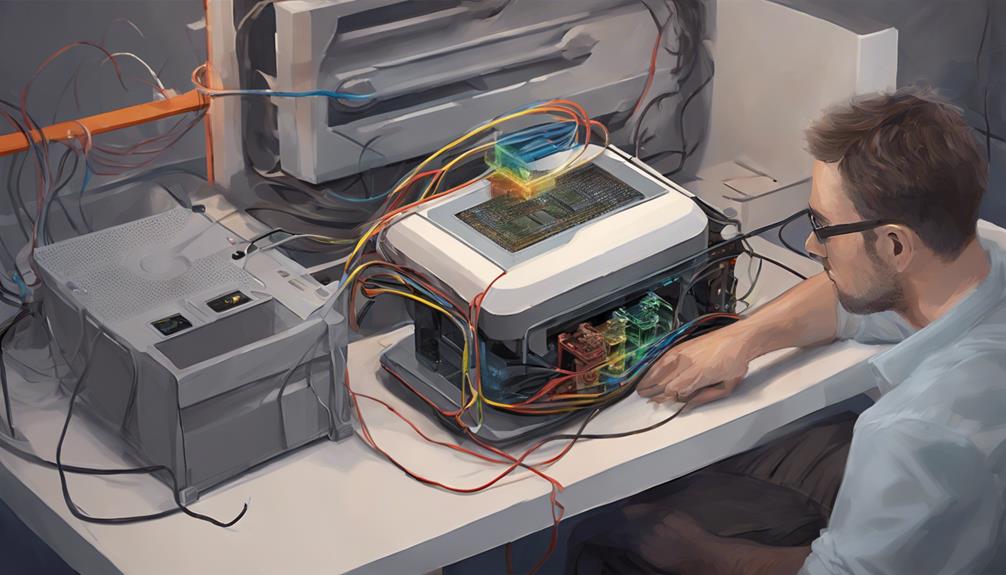

Hardware problems, such as damaged cables or faulty welds on the fan plate, can also lead to cooling fan malfunctions. Check for any external objects that might be obstructing the fan's operation. Additionally, make sure all layer-fan-related settings are properly enabled in the slicer to avoid any potential conflicts.

Troubleshooting Tips for Cooling Fan Issues

To troubleshoot cooling fan issues on your 3D printer efficiently, consider examining the fan's connection points for any loose contacts. Check different control boards and connection tabs for compatibility problems.

Swap the fan plug for better connection and inspect fan cables for damage due to movement. Utilize a multimeter to detect cut wires and make sure there are no faulty welds on the fan plate causing connection failures.

If you suspect hardware-related issues, verify the operating voltage of the fan, check current consumption compatibility, test the control board with a multimeter, and inspect connection pins for loose contacts. These troubleshooting steps can help you identify and resolve cooling fan issues on your 3D printer effectively.

Cooling Fan Settings and G-Code Verification

For peak cooling efficiency, adjust the rotation speed of the cooling fan in accordance with your printing requirements. Make sure the fan is set to the appropriate speed to prevent overheating and maintain print quality.

Check your slicer settings to enable or disable the fan at specific heights during printing. Verify the G-code for the M106 command to control the fan speed accurately. Confirm that the extruder is associated with the correct fan in the G-code.

Adjust the PWM pulse width to regulate the fan speed effectively. By fine-tuning these settings and verifying the G-code, you can optimize cooling performance and enhance the quality of your 3D prints.

Hardware-Related Cooling Fan Problems

Adjusting the rotation speed of the cooling fan based on your printing requirements is crucial for maintaining peak cooling efficiency and preventing overheating, especially when dealing with hardware-related cooling fan problems.

If you encounter issues like a broken cooling fan, start by verifying the operating voltage and checking the current consumption compatibility. Test the control board using a multimeter to confirm proper functionality. Additionally, check for loose contact in the connection pins, as poor connections can lead to fan failures.

Recommended Settings and Wiring Checks

Guaranteeing peak cooling efficiency involves setting the fan full at height and checking the wiring for continuity using a multimeter. To optimize your 3D printer's cooling fan performance, consider the following recommendations and wiring checks:

- Set the fan full at height to maximize cooling effectiveness.

- Adjust regular/maximum fan speed settings to prevent fan failure.

- Define regular/maximum fan speed thresholds for efficient cooling.

- Verify cooling fan wiring with a multimeter to guarantee continuity.

Frequently Asked Questions

Can Printing Parameters Affect Cooling Fan Performance?

Yes, printing parameters can greatly impact cooling fan performance. Adjusting slicer settings, like fan speed and layer cooling options, can optimize cooling efficiency. Verify proper settings to prevent overheating and achieve high-quality prints.

How Can I Address Compatibility Issues With Control Boards?

Address compatibility issues with control boards by swapping fan plugs for better connections. Use a multimeter to check for wire cuts. Verify control board compatibility with a multimeter. Confirm tight connection pins for smooth operation.

What Should I Do if the Fan Cables Are Damaged?

If the fan cables are damaged, carefully inspect them for cuts or breaks. Replace damaged cables with new ones to guarantee proper functioning. Avoid using the printer until the cables are fixed to prevent any further issues.

Is There a Way to Verify the Operating Voltage of the Fan?

Feeling lost in the tech jungle? No worries! You can easily verify the fan's operating voltage. Grab a multimeter, check the fan's specs, and measure the voltage. With a little know-how, you'll be back on track!

How Do I Define the Regular/Maximum Fan Speed Threshold?

To define the regular/maximum fan speed threshold, adjust settings in your slicer software. Locate options for fan speed control and set limits based on your printer's capabilities. Testing different speeds can help you find the best threshold for efficient cooling.

Conclusion

To sum up, troubleshooting cooling fan issues on a 3D printer can be easily done by following simple steps.

By checking connections, inspecting control boards, and using a multimeter, identifying and resolving problems with the cooling fan can be a straightforward process.

Even if you encounter difficulties, remember that with patience and persistence, you can successfully troubleshoot and guarantee the efficient operation of your 3D printer's cooling fan.