When perfecting your top 3D print layers, taking a closer look at a few key elements can make a significant difference in your final results. By understanding how adjusting top layer thickness, infill density, and ironing techniques can impact your prints, you set the stage for achieving smoother, more flawless outcomes. These subtle tweaks hold the potential to elevate the quality of your top layers, but the real magic lies in the careful balance and finesse of these adjustments. Curious to uncover the nuances that can transform your 3D prints?

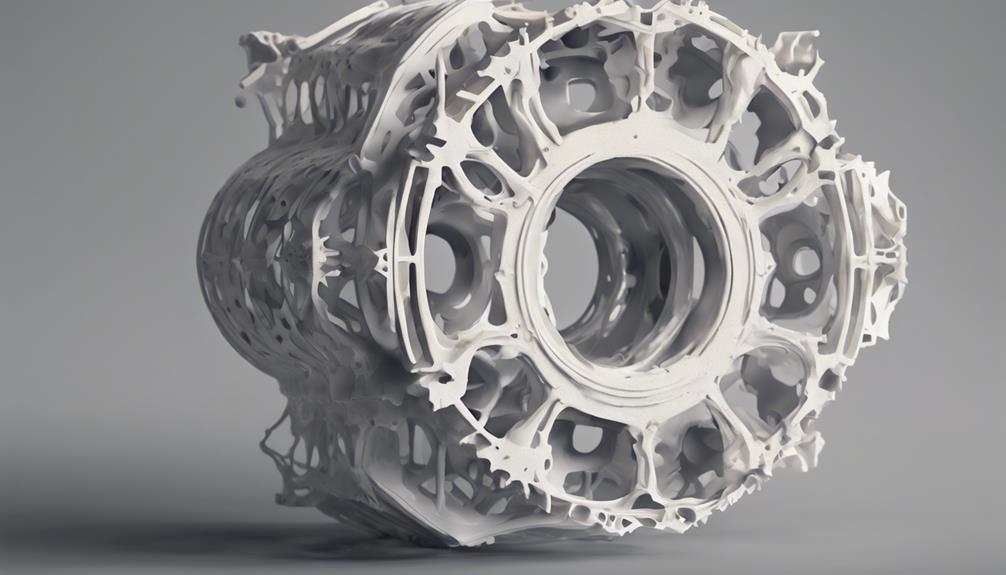

Preventing Sagging With Top Layer Thickness

To prevent sagging in your 3D prints, consider increasing the top layer thickness for added structural support. When the top layers are too thin, especially in areas with no underlying infill, the print can start to sag or deform.

By increasing the top layer thickness, you provide more material for the uppermost layers, enhancing their ability to maintain shape and prevent drooping. This simple adjustment can greatly improve the overall quality of your prints, especially in sections where importance and stability are key.

Experiment with slightly thicker top layers to find the best balance between structural integrity and print speed, ensuring that your 3D models come out with a professional finish.

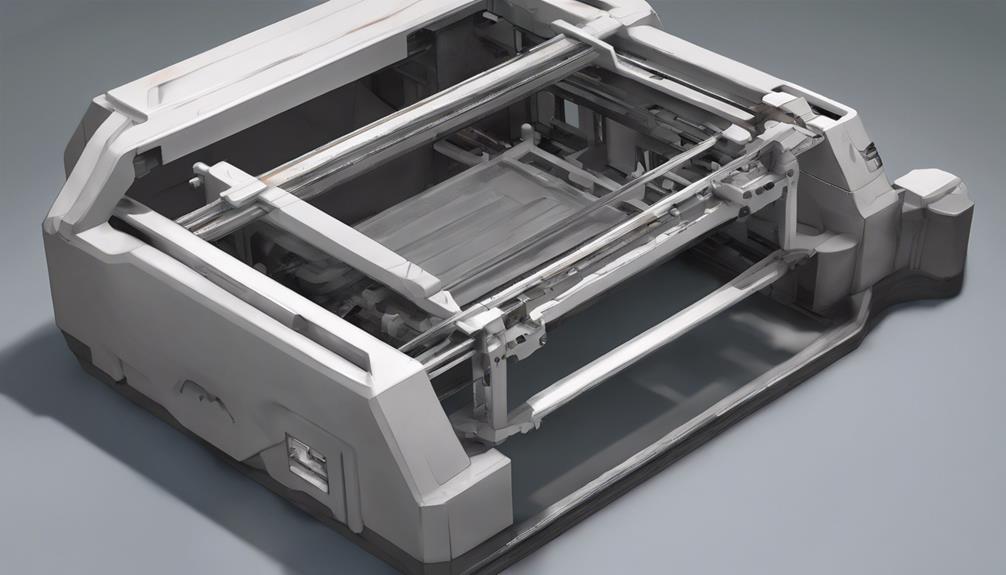

Improving Support With Infill Density

Increasing the infill density enhances the structural support of your 3D prints, ensuring better quality and stability. To improve support with infill density, consider the following tips:

- Increase infill percentage gradually to find the right balance.

- Experiment with different infill patterns for varied support.

- Utilize higher infill densities for parts requiring more strength.

- Check for over-extrusion issues that may affect infill quality.

Addressing Holes and Gaps in Top Layers

Wondering how to effectively address holes and gaps in your 3D print's top layers? To tackle these issues, consider adjusting your top layer thickness, increasing infill density, and checking for under-extrusion. Here's a helpful table to guide you:

| Problem | Solution | Action |

|---|---|---|

| Holes in Top Layers | Increase top layer thickness | Adjust top layer settings in slicer |

| Gaps in Top Layers | Increase infill density | Modify infill settings for denser print |

| Under-extrusion | Check extrusion multiplier and temperature | Calibrate extrusion settings accurately |

| Nozzle Condition | Ensure nozzle is clean and in good condition | Regularly maintain and clean the nozzle |

Enhancing Top Layer Quality With Ironing

Ironing is a technique in 3D printing that smooths out the top layers, resulting in a more polished finish.

To make the most of ironing, consider the following tips:

- Understand ironing in 3D printing for smoother surfaces

- Know when to use ironing for best results

- Be aware of potential filament jamming during ironing

- Consider extra printing time for ironing

Troubleshooting Pillowing Issues

To troubleshoot pillowing issues in your 3D prints, start by adjusting your top layer thickness and infill density. Increasing the top layer thickness can help create a smoother finish, while boosting the infill density provides a stronger foundation to prevent pillowing.

Additionally, consider verifying that your cooling system is functioning at its best to aid in solidification and prevent overheating issues that can lead to pillowing. If necessary, explore modifications to enhance cooling efficiency.

Frequently Asked Questions

How Can I Reduce Stringing and Improve Top Layer Quality Simultaneously?

To reduce stringing and improve top layer quality simultaneously, adjust retraction settings to minimize stringing between prints. Optimize cooling fan speed to enhance top layer quality. Fine-tune retraction distance and speed for cleaner prints overall.

Is Ironing Suitable for All Types of 3D Printing Filaments?

Ironing in 3D printing, while effective for smoother finishes on flat surfaces, may not suit all filaments. Consider compatibility with the filament type before using ironing. Adjust settings for best results.

Can I Adjust Ironing Settings Mid-Print for Different Effects?

You can't adjust ironing settings mid-print for different effects. Make necessary changes before starting. Understanding ironing and its impact is important. Experiment on test prints to find the best settings. Ironing can enhance top layer quality greatly.

What Should I Do if Ironing Causes Nozzle Clogging or Jamming?

If ironing causes nozzle clogging or jamming, pause the print immediately. Clear any obstructions using proper tools. Check filament diameter and nozzle condition. Adjust temperature settings gradually and resume printing. Monitor for improved flow and consistency.

Are There Specific Considerations for Ironing on Textured Surfaces?

Looking to iron on textured surfaces? Adjust settings carefully for best results. Smooth out layers effectively without clogging. Is it challenging? Experiment with settings until you achieve the desired finish. Happy printing!

Conclusion

Now that you have the tools to troubleshoot and enhance your top 3D print layers, it's time to put your skills to the test.

By adjusting top layer thickness, infill density, and utilizing ironing techniques, you can achieve flawless top layers in your prints.

Remember, the key is to experiment and stay patient – the results will be worth the effort.

Happy printing!