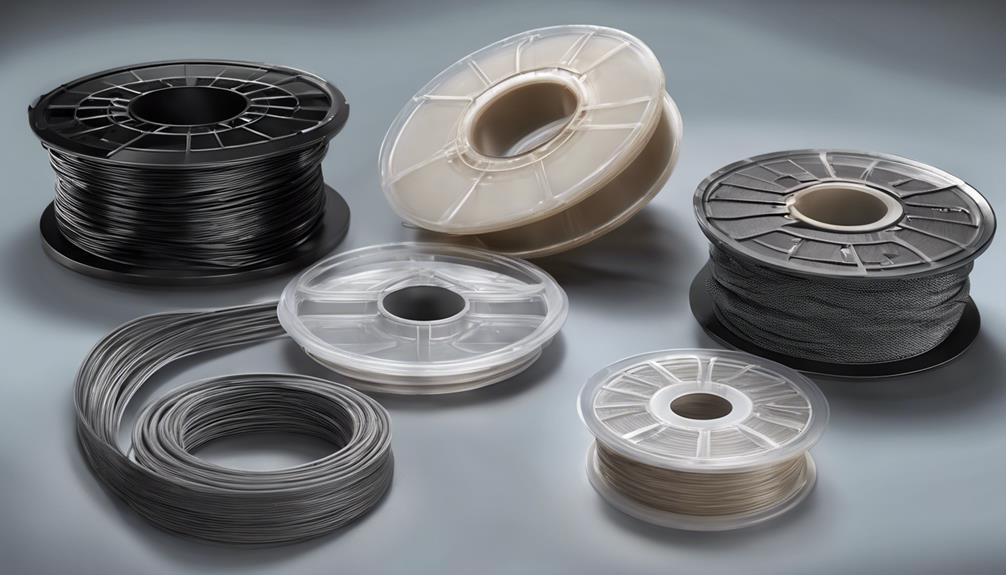

When it comes to advancing 3D printing filament compatibility, you may want to explore the significant impact of delving into innovative filament options like Nylon, Polycarbonate, and TPU. These materials offer a wide range of benefits, but delving into their full potential requires more than just filament selection. Delving into the intricacies of printer modifications, extruder systems, and environmental factors is essential. By understanding how these elements interact, you can truly revolutionize your 3D printing experience and achieve remarkable results.

Advanced Filament Options and Modifications

When considering advanced filament options and modifications for your 3D printer, it's crucial to grasp the compatibility and potential enhancements these filaments can offer.

Upgrading your printer to handle filaments like Nylon, Polycarbonate, or TPU can unlock a world of possibilities for your printing projects. These filaments, while necessitating certain modifications for best printing results, bring added strength, flexibility, and heat resistance to your creations.

Extruder Systems and Compatibility Considerations

Considering the compatibility of extruder systems is vital for optimizing your 3D printing experience. When choosing filaments, understanding the differences between Bowden and Direct Drive extruders is essential. Bowden setups use a long tube to guide filament to the hot end, making them better suited for rigid filaments. Direct Drive systems have the extruder motor located near the hot end, allowing for more control over flexible materials. Here is a comparison table to help you grasp the key variations:

| Aspect | Bowden Extruder | Direct Drive Extruder |

|---|---|---|

| Filament Control | Less precise due to tube length | More precise with motor closer to hot end |

| Compatibility | Better for rigid filaments like PLA and ABS | Suitable for flexible materials like TPU |

| Retraction | More challenging due to filament path | Easier retraction settings for cleaner prints |

Optimizing Filament Printing Environments

To improve your 3D printing results, optimizing the printing environment for your chosen filament is vital.

When using filaments like PLA or PETG that don't require an enclosure, make sure to have good ventilation to prevent fumes build-up.

For filaments like ABS or Nylon that benefit from an enclosure, consider using non-flammable options like those offered by Creality. Enclosures can help maintain stable temperatures, reducing warping in larger prints.

It's important to match the filament with the appropriate environment to achieve the best print quality. Experiment with different settings and observe how changes in the printing environment affect your final prints, making adjustments as needed for excellent results.

Managing High Temperatures and Filament Types

Mastering high temperatures and different filament types is essential for optimizing your 3D printing process. When managing high temperatures and filament types, consider these key points:

- Melting Temperatures: Understanding the specific melting points of different filaments is critical to prevent clogs and ensure smooth printing.

- Compatibility with Hot End: Check if your printer's hot end can reach the necessary temperatures for the filament you want to use.

- PTFE Tube Concerns: Be cautious when printing high-temperature filaments with PTFE tubes, as they may degrade and release harmful fumes.

Nozzle Selection for Enhanced Compatibility

Improve your 3D printing compatibility by selecting the best nozzle for your filament type. Different filaments require specific nozzle materials to guarantee excellent printing results.

For PLA and ABS, a brass nozzle works well due to its good thermal conductivity. When printing abrasive filaments like carbon fiber, a hardened steel or ruby nozzle is more suitable to prevent wear.

Stainless steel nozzles are ideal for filaments that emit hazardous fumes, such as Nylon, as they're more resistant to corrosion. Consider the filament's properties and printing requirements when choosing between brass, stainless steel, hardened steel, or ruby nozzles to enhance compatibility and achieve superior printing outcomes.

Frequently Asked Questions

Can I Mix Different Filament Types/Colors to Create Unique Prints?

Yes, you can mix different filament types/colors to create unique prints. Experiment carefully, ensuring compatible melting temperatures and extrusion rates. Use a dual extruder or manually switch filaments for multicolor designs. Enjoy the creative possibilities of blending filaments in your prints!

How Can I Reduce Stringing and Oozing During 3D Printing?

Want to reduce stringing and oozing during 3D printing? Adjust retraction settings for less stringing, fine-tune temperature for less oozing, guarantee proper cooling, and check filament quality. These tweaks can enhance your print quality substantially.

Is It Possible to 3D Print With Recycled or DIY Filaments?

Yes, you can 3D print with recycled or DIY filaments. Experiment with shredded plastics or recycled materials like old CDs. Guarantee proper extrusion consistency and filament diameter. Test in small batches first. Enjoy the eco-friendly approach to filament use.

What Are the Best Practices for Storing and Handling Filaments?

When storing and handling filaments, maintain a dry environment to prevent moisture absorption, impacting print quality. Use airtight containers or desiccant packs. Store in a cool, dark place away from UV light sources.

How Do I Troubleshoot Under-Extrusion Issues in My Prints?

When troubleshooting under-extrusion in your prints, begin by checking the nozzle for clogs. Verify proper filament diameter, adjust extrusion multiplier, and examine filament path for obstructions. Fine-tune extrusion settings, consider nozzle wear, and maintain consistent filament flow.

Conclusion

As you fine-tune your 3D printer and experiment with advanced filaments like Nylon and TPU, you're on the brink of discovering a world of possibilities. Picture a sleek, high-tech machine effortlessly producing intricate designs with strength and precision.

With the right modifications and settings, you're paving the way for the future of 3D printing. Keep pushing boundaries, and watch your creations come to life in ways you never thought possible.