In the domain of resin printing, the importance of proper support structures cannot be overstated. These supports serve as the unsung heroes of the printing process, quietly but notably influencing the outcome of each intricate design. From ensuring stability to enhancing adhesion, the role of supports is multifaceted and vital for achieving flawless prints. However, the nuances of support placement go beyond mere functionality; they can impact the overall quality and success of a print in ways that may surprise even seasoned enthusiasts. Understanding the intricate dance between the design, support placement, and material selection is paramount for those seeking to elevate their resin printing endeavors to new heights.

Importance of Proper Support Placement

Why is proper support placement essential for successful resin 3D printing?

Proper support placement plays a significant role in ensuring the stability and quality of resin prints. Supports are necessary to uphold overhanging features and intricate geometries during the printing process, preventing deformities or failed prints.

Incorrect support placement can lead to structural weaknesses, misshapen details, or detachment issues, compromising the overall print's integrity. By strategically positioning supports, users can optimize adhesion, minimize material usage, and facilitate easier post-processing tasks like support removal.

Therefore, meticulous attention to support placement is critical for achieving high-quality, accurate resin prints with intricate designs and complex structures.

Functionality of Tree Supports

The functionality of tree supports in resin 3D printing showcases their effectiveness in providing structural rigidity and minimal contact with the printed object. These supports branch out from a base structure, allowing for stability while minimizing interference with the model.

Tree supports are designed to offer reliable support during the printing process, especially for intricate or delicate designs. By strategically placing these supports, users can guarantee successful print outcomes with minimal post-processing requirements.

Compared to traditional supports, tree supports excel in minimizing touchpoints with the model, reducing the chances of surface imperfections and simplifying the removal process. Their unique design enhances printing efficiency and helps in achieving high-quality resin prints.

Understanding Support Differences

In the domain of resin and filament 3D printing, a critical aspect to grasp is the disparity in support structures utilized by these two printing technologies. Understanding Support Differences is essential for optimizing print quality and success. Here are key distinctions to take into account:

- Resin printers use tree supports for rigidity and minimal contact with the object.

- FDM slicers generate lines or grid supports, differing from resin supports.

Resin supports are thinner and designed for tensile strength, while FDM supports are thicker for mechanical stress. Tree supports in FDM printing are less popular due to mechanical requirements and material consumption.

Guidelines for Optimal Support Placement

For successful resin 3D printing, precise support placement is paramount to guaranteeing stable adhesion and ideal layer formation. To achieve ideal support placement, it is essential to make sure the first layer prints correctly with strong adhesion to the build plate.

Utilizing features like PAD (Raft) can help contain supports and prevent detachment risks. Rotating objects at an angle of 10 to 30 degrees can minimize supports and aid in layer removal. Avoid placing large layers parallel to the build plate to prevent failures.

Prioritizing proper support placement over material savings is vital to avoid failed prints. Following these guidelines will help in achieving successful resin prints with high-quality outcomes.

Impact of Support Structures

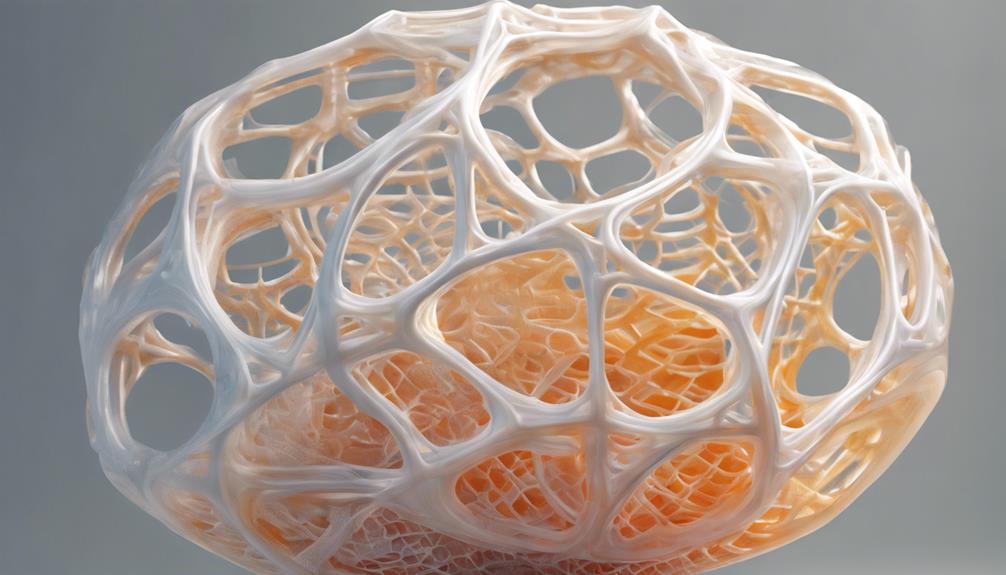

Support structures play a crucial role in determining the overall success and quality of resin 3D prints. The impact of support structures is significant and can greatly influence the final outcome of a print.

- Supports guarantee proper adhesion and stability throughout the printing process.

- Improper support placement can lead to print failures and defects.

- The design of support structures affects the overall aesthetics and functionality of the final print.

- Well-designed supports contribute to smoother surfaces and intricate details in resin prints.

Significance of Support Material Selection

Selecting the appropriate support material is a vital decision that greatly influences the outcome and quality of resin 3D prints. The support material must be compatible with the resin used, ensuring proper adhesion during printing and easy removal afterward.

Factors such as solubility in post-processing solutions, thermal properties, and ease of removal play a significant role in the selection process. Some common support materials include light-curable resins similar to the main resin used, breakaway supports that can be manually removed, and dissolvable supports that can be dissolved in specific solutions.

Choosing the right support material can help achieve cleaner prints, reduce post-processing time, and improve overall print success rates.

Support Placement Best Practices

The meticulous placement of supports in resin 3D printing greatly impacts the structural integrity and overall quality of the printed object. Proper support placement is vital for successful resin prints.

To achieve best results, consider the following best practices:

- Make sure the first layer prints correctly with strong adhesion to the build plate.

- Utilize features like PAD (Raft) to contain supports and prevent detachment risks.

- Rotate objects at an angle of 10 to 30 degrees to minimize supports and aid in layer removal.

- Avoid placing large layers parallel to the build plate to prevent failures.

Frequently Asked Questions

Can Resin Prints Be Successful Without Any Supports?

Resin prints generally require supports for stable layer formation. Attempting resin printing without supports is not advisable, as supports are essential for adhesion and structural integrity. Proper support placement is key for successful resin prints.

Why Are Tree Supports More Common in Resin Printing?

Tree supports are more common in resin printing due to their rigidity and minimal contact with the object, optimizing print quality. Their design enhances stability and reduces post-processing efforts, making them a preferred choice for achieving successful resin prints.

What Are the Key Differences Between Resin and FDM Supports?

The key differences between resin and FDM supports lie in their design and purpose. Resin supports are thinner and focus on tensile strength, while FDM supports are thicker for mechanical stress. Understanding these variances is essential for print quality optimization.

How Can Support Placement Affect Print Quality?

Proper support placement is crucial in resin printing as it directly impacts print quality. Correctly positioned supports guarantee adhesion, minimize detachment risks, and aid in successful layer formation. Strategic support placement is key for high-quality resin prints.

Does Support Material Impact Print Outcome Significantly?

Support material plays a significant role in print outcomes in resin printing. Factors such as adhesion strength, compatibility with the resin, and ease of removal impact the final quality. Choosing the right support material is essential for successful prints.

Conclusion

In the intricate world of resin printing, proper support placement is the key to success. Like a sturdy tree in a forest, tree supports provide stability and enhance the quality of prints.

Understanding the differences between resin and FDM supports is essential for achieving excellent results. By following guidelines for support placement and selecting the right materials, resin prints can be produced with impeccable adhesion and intricate details.

Support placement is the foundation for creating stunning, high-quality final products.