Did you know that Blender's capabilities expand far beyond just creating animations and graphics? Explore how Blender can revolutionize your approach to 3D printing, opening up a world of possibilities for your projects. Delve into how this versatile software can streamline the design process and elevate the quality of your prints, making your creations stand out. Discover the secrets behind harnessing Blender's tools to unleash the full potential of 3D printing, and take your designs to the next level.

Blender's Versatility in 3D Printing

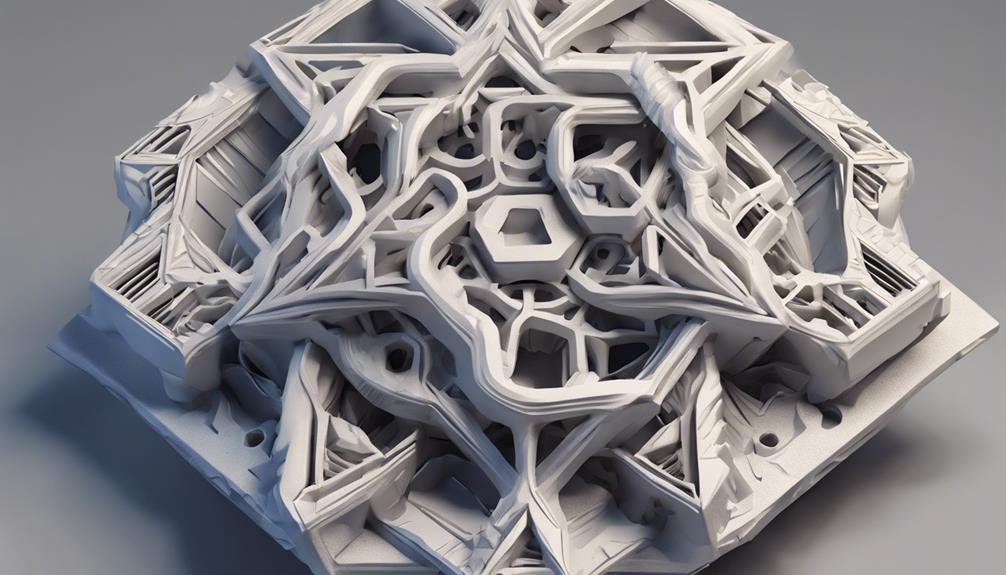

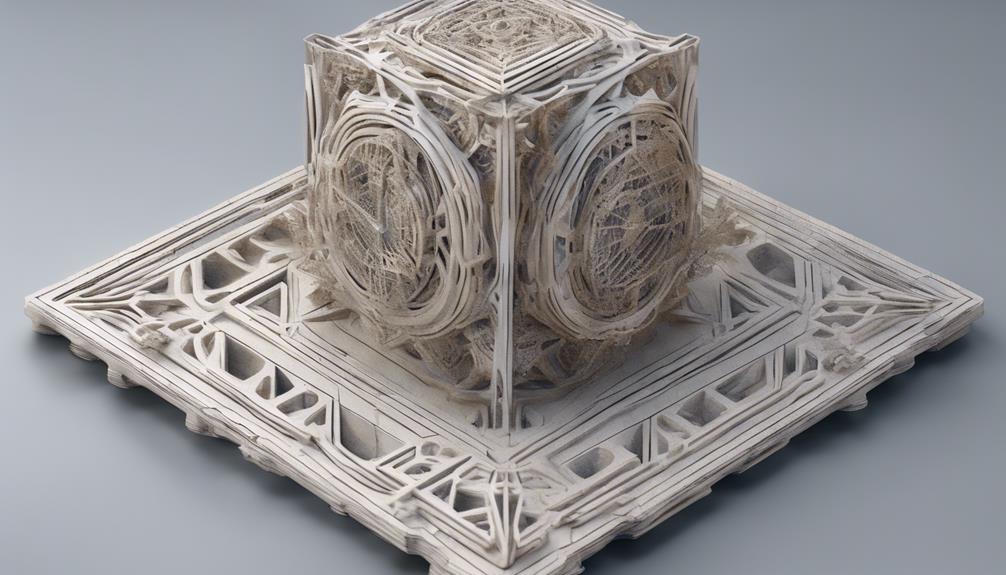

Blender's flexibility in 3D printing allows for creative and intricate designs to come to life with ease. With its diverse set of tools, you can easily sculpt, texture, and refine your models, ensuring they're ready for the printing process.

The software's adaptability empowers you to experiment with various shapes and structures, giving you the freedom to explore your artistic vision. Blender's intuitive interface streamlines the design process, making it accessible for both beginners and experienced users.

Harnessing Blender's Organic Modeling Tools

By tapping into Blender's organic modeling tools, you can awaken your creativity and sculpt intricate, natural designs with ease. These tools allow you to shape forms seamlessly, mimicking the flow of nature's curves and textures.

From crafting lifelike characters to detailed plant structures, Blender's organic modeling capabilities empower you to create visually stunning 3D prints. With features like sculpting brushes, dynamic topology, and texture painting, you can breathe life into your designs with a touch of realism.

Embrace the fluidity of organic modeling in Blender to unlock your artistic vision and explore the endless possibilities of creating organic, nature-inspired prints that captivate and inspire.

Overcoming Challenges in Blender Printing

To optimize your 3D printing results in Blender, tackle common challenges by adjusting model settings and utilizing the 3D Print Toolbox.

When facing issues like non-manifold geometry, intersecting faces, or thin walls that can hinder the printing process, make certain your model is watertight by checking for any gaps or overlaps. Use Blender's features like the 3D Print Toolbox to analyze and fix potential errors before sending your design to the printer.

Adjusting the scale, thickness, and orientation of your model can also help overcome challenges. By fine-tuning these aspects within Blender, you can enhance the printability of your designs and achieve smoother printing experiences.

Utilizing Blender's 3D Print Toolbox

Utilize Blender's 3D Print Toolbox to analyze and optimize your models for successful 3D printing. This toolbox provides essential tools to make sure your designs are print-ready. The features help you identify and rectify potential printing issues, ultimately leading to smoother and more accurate prints. To give you a clearer picture, here is a table showcasing some key tools found in Blender's 3D Print Toolbox:

| Tool | Function | Benefit |

|---|---|---|

| Overhangs | Detects overhangs | Prevents mid-print collapses |

| Wall Thickness | Checks thickness | Ensures model stability |

| Clearances | Verifies clearances | Avoids print merging issues |

| Non-Manifolds | Identifies errors | Fixes non-printable geometry |

| Intersections | Highlights overlaps | Averts unwanted print errors |

Exploring Blender's Printing Capabilities

Explore how Blender harnesses the potential of 3D printing with its versatile tools and features. Blender's printing capabilities offer a range of options for your projects. Here are three key aspects to explore:

- Advanced Mesh Editing: Blender provides intricate mesh editing tools allowing you to refine and perfect your 3D models before printing.

- Customizable Supports: With Blender, you can create tailored supports for your prints, ensuring stability and quality during the printing process.

- Simulation Features: Blender offers simulation features that enable you to preview how your model will behave during printing, helping you optimize for successful outcomes.

Blender Vs. Specialized 3D Printing Software

Compare Blender's capabilities for 3D printing with specialized software designed specifically for this purpose to understand the unique advantages each offers in optimizing printing processes.

| Aspect | Blender | Specialized Software |

|---|---|---|

| User Interface | Complex interface with a learning curve. | Intuitive layout tailored for 3D printing tasks. |

| Features | Versatile for various design applications. | Focused tools for precise and technical prints. |

| Printing Analysis | Requires addons for detailed print analysis. | Built-in analysis tools for print optimization. |

Mastering Blender for 3D Printing

Begin mastering Blender for 3D printing by delving into its versatile tools and features. To make the most of Blender for 3D printing, consider the following:

- Model Preparation: Guarantee your models are solid and suitable for 3D printing by using Blender's 3D Print Toolbox for analysis and error prevention.

- Support Structures: Learn how to create and customize support structures within Blender to guarantee successful 3D prints for intricate designs.

- Optimizing Meshes: Master techniques to optimize mesh geometry in Blender, reducing file size and ensuring smoother, more efficient 3D printing processes.

Frequently Asked Questions

Can Blender Be Used for Industrial and Technical 3D Printing Designs?

For industrial and technical 3D printing designs, Blender may not be the best choice due to its focus on organic shapes and artistic designs. Consider software like Fusion360 for precise and technical objects.

How Does Blender's Modeling Tools Compare to Specialized CAD Software?

When comparing Blender's modeling tools to specialized CAD software, you'll find Blender excels in artistic designs and organic shapes. However, for precise and technical objects, like in Fusion360, specialized CAD software might be better suited.

Is Blender Suitable for Creating Precise and Accurate Measurements for 3D Printing?

For creating precise and accurate measurements for 3D printing, Blender may not be the best choice due to its focus on artistic designs and organic shapes. Consider using specialized CAD software like Fusion360 for technical objects.

What Are the Limitations of Using Blender for 3D Printing Compared to Other Software?

When using Blender for 3D printing, be aware of limitations compared to other software. Blender excels in organic shapes but struggles with precise technical objects. Utilize tools like 3D Print Toolbox for stability. Explore alternatives for intricate designs.

Does Blender Offer Specialized Features for Optimizing 3D Prints for Different Printers?

Blender doesn't offer specialized features for optimizing 3D prints for different printers. However, with its community support, you can find add-ons and tools like the 3D Print Toolbox to help analyze models and avoid printing errors.

Conclusion

You've discovered the truth: Blender is the ultimate tool for unlocking the full potential of 3D printing. Its versatile platform, organic modeling tools, and 3D print toolbox make it a powerhouse for creating stunning designs.

Don't be swayed by specialized software – Blender is the key to mastering 3D printing. Embrace its capabilities and watch your creative visions come to life in ways you never thought possible.

Blender is the future of 3D printing – embrace it now.