When it comes to 3D printing, mastering supports is an essential skill that can enhance the quality of your prints greatly. By honing in on the intricacies of support types, patterns, and densities, you can open up a world of possibilities in optimizing your printing process. Understanding the nuances of support placement and configurations can make all the difference in achieving flawless results. Stay tuned to discover how these insider tips can transform your 3D printing experience and take your creations to the next level.

Types and Characteristics of Supports

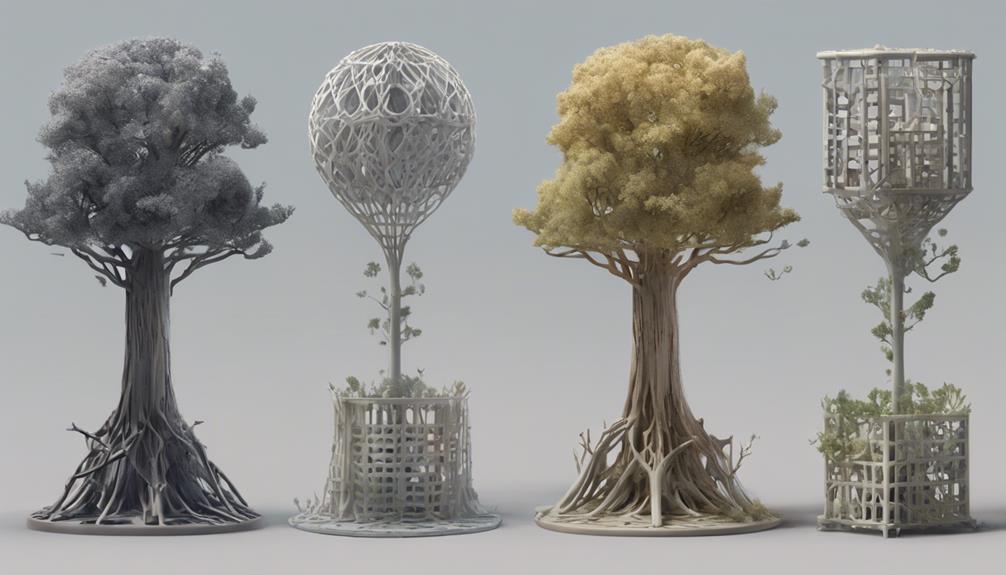

When exploring types and characteristics of supports in 3D printing, it's important to understand the distinctions between Normal and Tree supports. Normal supports are ideal for flat or boxy models, as they can be easily pried out after printing.

In contrast, Tree supports are better suited for organic figures, offering a more solid and intricate structure but increasing slicing time for larger models. While Normal supports are straightforward to remove, Tree supports provide stronger reinforcement.

Choosing between these support types depends on the complexity and design of your 3D model. Experimenting with both options will help you determine which support type best suits your printing needs and results in successful, high-quality prints.

Support Patterns and Configurations

To further grasp the intricacies of 3D printing supports, let's now explore the various patterns and configurations that play a crucial role in the printing process. Slicers offer strong or flimsy support patterns. Grid patterns provide robust support but can be challenging to remove. On the other hand, flimsy patterns like lines are easier to detach post-printing.

Opting for flimsy structures not only speeds up printing but also conserves material. Techniques such as using a support brim or increasing the Support Wall Line Count can bolster support strength. By selecting the most suitable pattern and configuration for your specific model, you can guarantee successful printing outcomes while facilitating easier support removal during finishing touches.

Support Placement and Density

Understanding the importance of support placement and density enhances the quality of your 3D printing results. When considering support placement, you must decide whether supports should be located everywhere or only touching the build plate.

For instance, Tree supports start at the build plate and branch out, providing stability for complex shapes. Support density, on the other hand, refers to the number of support lines within the structure. Starting at 20% density is generally recommended for achieving best results.

Adjusting the density can impact print time and material usage, so finding the right balance is key. Experiment with different placements and densities to find what works best for your specific prints.

Best Practices and Settings for Ender 3

Considering the Ender 3 as your 3D printer, optimizing the settings and practices can greatly enhance your printing outcomes.

When setting up your Ender 3, make sure that overhang angles over 45º and bridges larger than 5mm have adequate support.

To access support settings in Cura, click on the hamburger icon. For best results, choose Normal support structure, Touching build plate placement, a 45º – 60º overhang angle, Zig Zag support pattern, and set the density to 20%.

These settings are ideal for your Ender 3 and can make a significant difference in the quality of your prints.

Expert Tips for Advanced Support Usage

When delving into advanced support usage in 3D printing, enhancing your understanding of intricate support structures and configurations is key. Experiment with different support patterns to find the balance between strength and ease of removal.

Consider utilizing grid patterns for robust supports or opting for flimsy patterns like lines for quicker post-processing. Adjusting support density can also impact the overall stability of your prints; starting at 20% density is a good baseline.

Remember to fine-tune settings based on your specific model requirements. By mastering advanced support usage, you'll be able to tackle complex prints with confidence and achieve high-quality results.

Keep exploring and refining your techniques to elevate your 3D printing skills to the next level.

Frequently Asked Questions

Can Supports Be Reused for Multiple Prints?

Yes, supports can be reused for multiple prints if they remain intact and undamaged. Reusing supports can save time and material costs. Remember to carefully remove and store them for future use to maintain print quality.

How Do Supports Affect Print Speed?

Supports impact print speed significantly. They add time for creation and removal. Choose patterns wisely for faster printing. Adjust density for strength. Balancing support needs with speed is key for efficient 3D printing.

Are There Alternatives to Traditional Supports?

When considering alternatives to traditional supports, you'll find options like dissolvable supports, breakaway supports, or even support-free designs. Exploring these alternatives can offer more efficient and smoother post-processing experiences in your 3D printing journey.

Can Supports Be Customized for Specific Models?

Yes, supports can be customized for specific models. By adjusting support placement, density, and structure type, you can tailor supports to the needs of your model. Experiment with different settings to optimize support removal and printing quality.

Do Supports Impact the Strength of the Final Print?

Supports impact the strength of the final print. They provide stability during printing, ensuring overhangs and bridges are properly supported. Removing them post-printing can affect the surface finish. Proper support settings are essential for durable 3D prints.

Conclusion

In the world of 3D printing, mastering supports is like building a strong foundation for a successful project. Remember, 'practice makes perfect' when it comes to experimenting with different support types, patterns, and settings.

By honing your skills and techniques, you can achieve high-quality prints with ease. So keep pushing the boundaries, trying new things, and never underestimate the power of a well-supported print.

Happy printing!