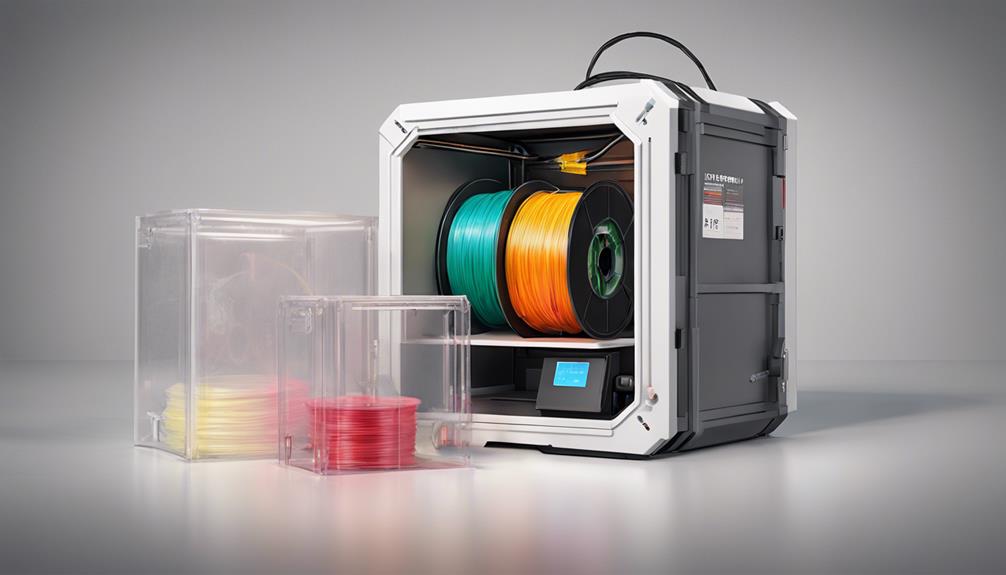

Understanding the critical role that proper filament storage plays in achieving high-quality 3D prints is paramount for enthusiasts and professionals alike. By exploring the innovative Drybox technology and its impact on print outcomes, a world of enhanced precision and consistency unfolds. Dive deeper into the intricacies of how Drybox systems revolutionize the 3D printing landscape, offering a glimpse into the future of flawless print execution and material preservation.

Benefits of Using Drybox Technology

The implementation of Drybox technology offers significant advantages in maintaining ideal filament conditions for high-quality 3D printing outcomes. By creating a controlled environment with low humidity levels, Dryboxes effectively prevent moisture absorption in filaments, especially those prone to degradation. This preservation guarantees that the material properties remain consistent, leading to smoother extrusion and enhanced print quality.

Additionally, Dryboxes help prevent nozzle clogging and other extrusion issues caused by moisture-related filament degradation. The use of Drybox technology is particularly beneficial for filaments like Nylon and TPU that are more sensitive to moisture, ensuring excellent printing conditions and reliable outcomes.

How Dryboxes Improve Print Quality

Implementing Drybox technology in 3D printing processes greatly enhances print quality by maintaining ideal filament conditions, guaranteeing consistent material properties, and preventing moisture-related extrusion issues.

By storing filament in a controlled environment with low humidity levels, Dryboxes effectively prevent moisture absorption, which can lead to filament degradation and printing imperfections. The controlled humidity inside a Drybox ensures that the filament remains dry and free from contaminants, resulting in smoother extrusion and improved layer adhesion.

This controlled environment also helps in preserving the mechanical properties of the filament, leading to more predictable and reliable print outcomes. Overall, Dryboxes play a pivotal role in optimizing print quality by safeguarding filament integrity throughout the printing process.

Key Features of Drybox Systems

Enhancing the efficiency of filament storage, Drybox systems incorporate essential features for maintaining ideal printing conditions.

Key features of Drybox systems include:

- Airtight seals to prevent moisture ingress

- Desiccant trays or compartments for humidity control

- Temperature regulation to guarantee the filament remains dry and at the best printing temperature

Additionally, some Drybox systems come equipped with filament spool holders to keep the filament organized and prevent tangling during printing.

The inclusion of a moisture level monitoring system allows users to track the humidity levels inside the Drybox, ensuring that the filament remains in a pristine condition for high-quality 3D printing results.

Tips for Effective Drybox Usage

For best results when utilizing a Drybox system for filament storage, consider implementing a regular maintenance schedule to guarantee consistent performance and filament quality.

To guarantee effective Drybox usage, follow these tips:

- Monitor Humidity Levels: Regularly check and maintain the humidity levels inside the Drybox to prevent moisture absorption by the filament.

- Clean the Drybox: Keep the Drybox clean from any dust or debris that could contaminate the filament and affect print quality.

- Calibrate Temperature Settings: Adjust the temperature settings of the Drybox according to the filament requirements to prevent overheating or underheating, ensuring optimum storage conditions.

Ensuring Optimal Filament Storage

To maintain the quality and integrity of filament storage, it is essential to establish a systematic approach that includes consistent monitoring of environmental conditions within the storage unit.

Proper storage is key for preserving filament quality and preventing moisture absorption, which can lead to printing defects. Filament should be stored in a dry and airtight container to shield it from humidity and dust. Utilizing desiccants like silica gel packets can further aid in maintaining ideal storage conditions.

Additionally, storing filament away from direct sunlight and extreme temperatures is critical to prevent material degradation. Regularly checking and replacing desiccants, as well as ensuring a controlled storage environment, are important practices to uphold filament quality and enhance 3D printing outcomes.

Frequently Asked Questions

Can I Use Any Plastic Container as a DIY Drybox?

Using any plastic container as a DIY drybox can work for filament storage, but it may not provide ideal humidity control. Consider adding desiccants like silica gel or airtight seals to improve effectiveness. Professional dryboxes offer superior moisture regulation for quality prints.

How Often Should I Replace the Desiccant in a Drybox?

Desiccant replacement frequency in a drybox depends on ambient humidity levels, desiccant capacity, and usage frequency. As a general guideline, replacing desiccant every 1-3 months maintains ideal moisture control, ensuring consistent filament quality and print results.

Is It Safe to Store All Types of Filaments in a Drybox?

Storing all types of filaments in a drybox is safe, although not all filaments require the same level of moisture protection. Highly hygroscopic materials like Nylon and TPU benefit most from drybox storage to maintain print quality.

Can I Use a Drybox for Filament Colors That Are Less Commonly Used?

Yes, a drybox can be used for less commonly used filament colors to maintain ideal printing conditions. While moisture absorption may vary, consistent storage in a drybox guarantees filament quality and reduces the risk of printing issues.

Are There Any Risks of Overheating Filament in a Drybox?

Overheating filament in a drybox poses risks of altering filament properties, leading to print quality issues. Monitoring temperature settings is essential to prevent overheating. Properly controlled dryboxes guarantee ideal conditions for filament storage, preserving material integrity for quality 3D prints.

Conclusion

To sum up, the utilization of Drybox technology serves as a shield, safeguarding the integrity of filament materials and elevating the standard of 3D printing.

Like a vigilant guardian, the airtight seals and desiccant trays within Drybox systems protect against the corrupting influence of moisture, ensuring that each print emerges as a masterpiece of precision and quality.

Embracing Drybox technology is akin to embracing excellence in the world of 3D printing.